In today’s semiconductor equipment, ceramic materials are widely used, so understanding how to continuously improve the precision and stability of semiconductor manufacturing, as well as which materials can maintain performance under the extreme conditions of chip production, is extremely important.

Key Materials for Semiconductor Applications

Al₂O₃ (Alumina)

Excellent insulation and mechanical strength.

AlN (Aluminum Nitride)

High thermal conductivity and low thermal expansion.

SiC (Silicon Carbide)

Outstanding chemical resistance and thermal shock tolerance.

Si₃N₄ (Silicon Nitride)

High strength and wear resistance.

Zerodur

Ultra-low thermal expansion for high-precision components.

Semiconductor Material Machining Precision Table

| Material | Roundness | Flatness | Concentricity | Parallelism | Roughness | Machining Accuracy |

| Alumina (Al₂O₃) | 0.001 mm | 0.001 mm (Φ300) | 0.005 mm | 0.001 mm | Ra0.03 µm | 0.001 mm |

| Aluminum Nitride (AlN) | 0.001 mm | 0.001 mm (Φ300) | 0.005 mm | 0.001 mm | Ra0.03 µm | 0.001 mm |

| Silicon Carbide (SiC) | 0.001 mm | 0.001 mm (Φ300) | 0.005 mm | 0.001 mm | Ra0.01 µm | 0.001 mm |

| Silicon Nitride (Si₃N₄) | 0.001 mm | 0.001 mm (Φ300) | 0.005 mm | 0.001 mm | Ra0.01 µm | 0.001 mm |

| Zerodur® | 0.001 mm | 1/20λ (Φ300) | 0.005 mm | 0.001 mm | Ra0.01 µm | 0.001 mm |

| Shapal HI-M | 0.001 mm | 0.001 mm (Φ300) | 0.005 mm | 0.001 mm | Ra0.04 µm | 0.001 mm |

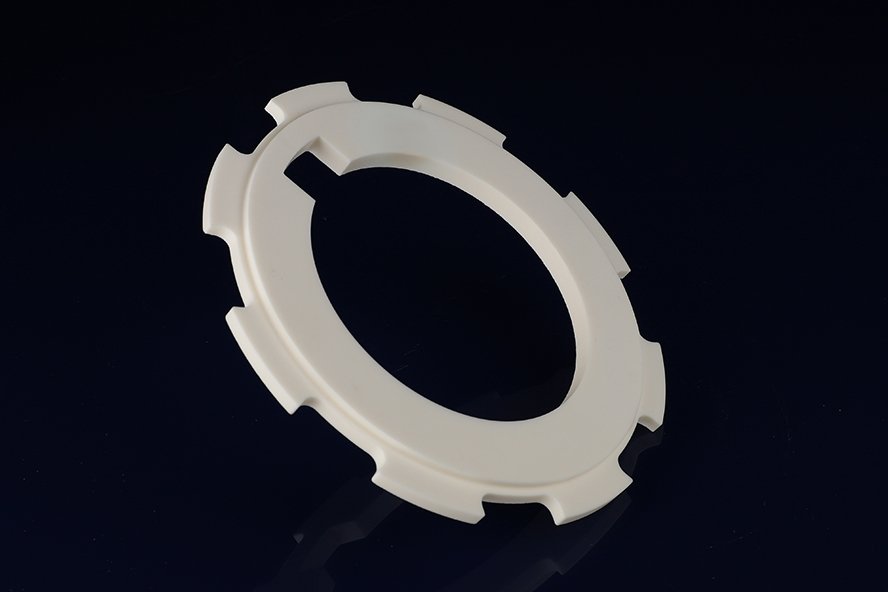

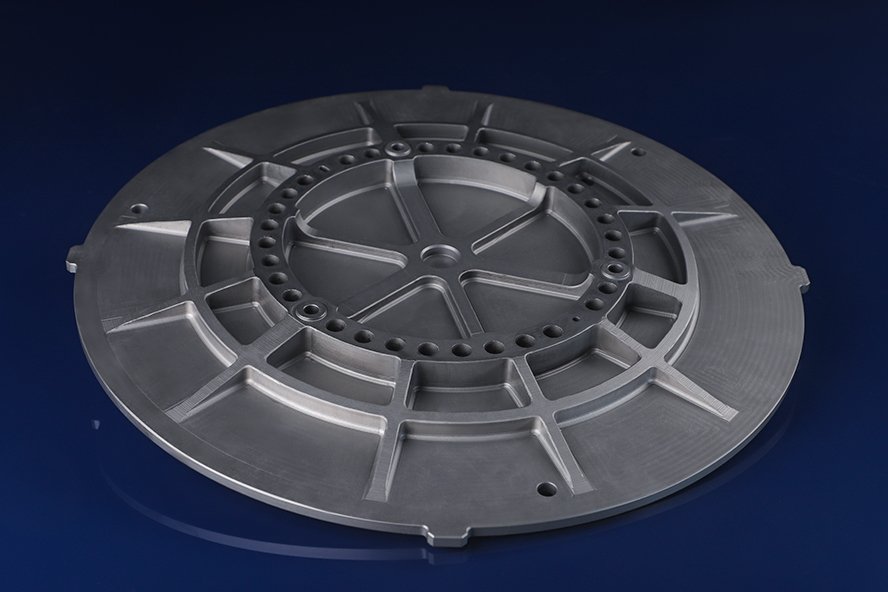

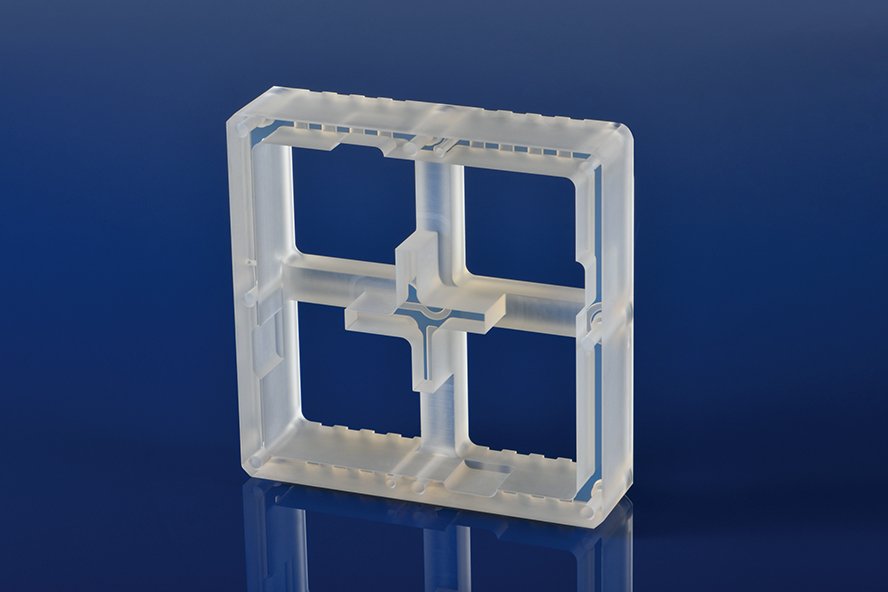

Common semiconductor components

Customized Ceramics Solutions

Tailored to Each Process Step – Materials and shapes optimized for thermal, electrical, and mechanical requirements.

Ultra-Precision Machining – Multi-axis CNC for micron-level accuracy and smooth surfaces (Ra0.01 µm).

High Purity & Cleanroom Compatibility – Low contamination and outgassing for critical semiconductor environments.

Rapid Prototyping & Custom Solutions – Small batch or high-volume production with strict process compliance.

Partner with a reliable semiconductor ceramics supplier to enhance your semiconductor manufacturing process with durable, high-performance ceramic components.

Not sure which ceramic material is suitable for your application? Contact our experts for assistance