In the modern precision optical field, the selection of low thermal expansion materials is particularly critical, such as the lenses of large optical telescopes and the optical components of laser gyroscopes. Zerodur or ULE Glass are both famous for their extremely low thermal expansion coefficients. So how do you choose which material to use as the first choice for your project? Today I will compare them from multiple dimensions to help you choose the right material more clearly.

Material Background

Zerodur

Zerodur glass is a material developed by Schott with a thermal expansion coefficient close to 0. It has high material uniformity and can provide 6 different thermal expansion levels. It supports high-precision machining and has a wide range of applications.

ULE Glass

The ULE (Ultra Low Expansion) glass series is developed by Corning. Its thermal expansion coefficient is even lower than Zerodur, and its maximum operating temperature can reach 800C°. At the same time, ULE has an extremely low density, which is very suitable for lightweight design

Thermal Performance Comparison

| characteristic | Zerodur | ULE Glass |

| Coefficient of Thermal Expansion (CTE) | 0 ± 0.02×10⁻⁶/K (Class 0) | 0.00 ± 0.03×10⁻⁶/°C |

| Maximum operating temperature | 600°C | 800°C |

| Thermal conductivity | 1.46 W/(m·K) | 1.31 W/(m·K) |

| Analyze | ||

| Zerodur’s CTE is close to absolute zero at a specific temperature, but ULE has a wider CTE range and better thermal stability. ULE’s high temperature tolerance is suitable for harsh environments such as semiconductor lithography (such as EUV) | ||

Mechanical and optical properties

| Parameter | Zerodur | ULE Glass |

| Density | 2.53g/cm³ | 2.21g/cm³ |

| Optical uniformity | ±5 × 10⁻⁷ | ±1 × 10⁻⁶ |

| Bending strength | ~40 MPa | ~30 MPa |

| Analyze | ||

| In terms of material density, ULE is lighter than Zerodur (13%), which is more suitable for weight reduction applications (such as space payloads). In terms of bending strength, Zerodur has better tolerance for precision machining. As for their optical uniformity, Zerodur’s optical uniformity is significantly better than ULE, which is suitable for applications that are sensitive to wavefront distortion, such as laser interferometers. | ||

Application

| Zerodur | ULE Glass |

| Laser gyroscope mirrors, brackets, and components | Astronomical optical mirror |

| Interferometers, optical tables, and length measurement systems | Lithography machine radiation mirror |

| Spectrometer optical components | Space telescope mirror blank |

| Fiber optic components and holders | Atomic clock resonator |

| Optical elements for space probes (e.g., comet probes) | Precision optical platform |

| Large ground-based telescope primary mirror | Laser rangefinder components |

Optical Glass Material Manufacturer

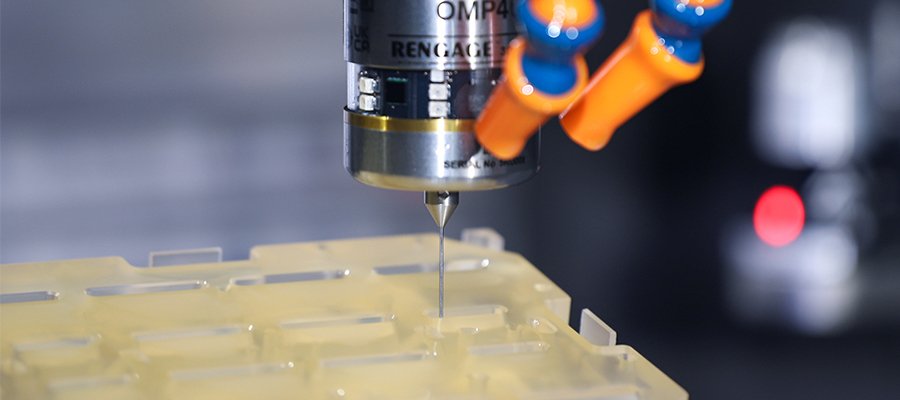

We have extensive knowledge and experience in the machining of optical glass materials, and provide customized machining of various high-precision optical glass materials, including special-shaped, round and curved surfaces, and have five-axis precision machining capabilities.

If you are selecting optical glass materials for your project, please contact our experts and we will provide strong support for your project.