半导体中的先进陶瓷

概述

先进陶瓷在半导体领域发挥着重要作用,被广泛应用于生产和制造工艺中。这些陶瓷材料以其独特的性能满足了半导体行业对高纯度、高性能和高可靠性的需求。主要应用和优势如下

应用场景

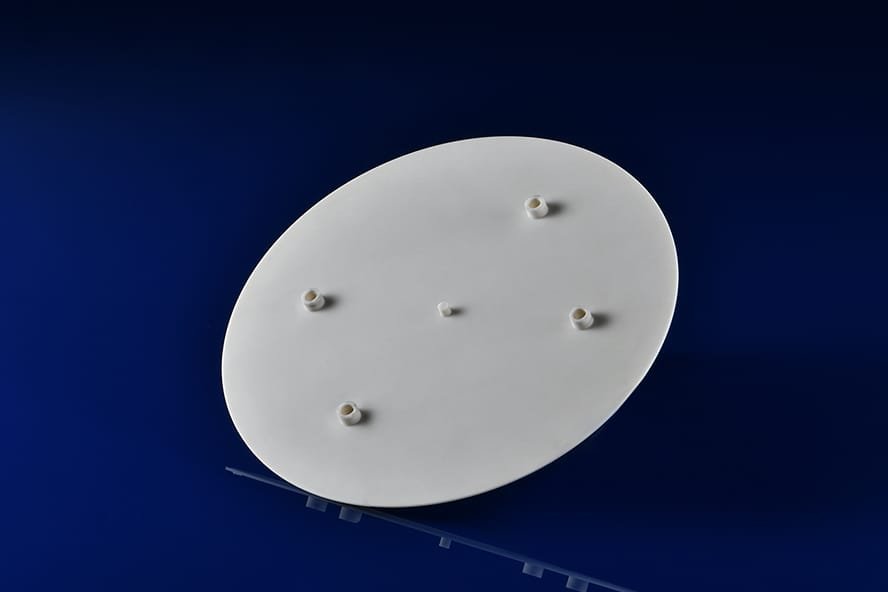

- 静电吸盘(ESC):用于固定硅晶片,以确保高精度加工。

- 绝缘元件:为等离子蚀刻和化学气相沉积 (CVD) 设备提供电气绝缘。

- 机械部件:提供高硬度和耐磨性,如导轨和支架。

- CMP 研磨垫和支撑环使用陶瓷元件,以确保化学和机械稳定性。

- 托盘和载体:耐高温和化学腐蚀,是半导体晶片退火和扩散的理想选择。

- 陶瓷基板(氮化铝、氧化铝):具有高导热性和绝缘性,是功率半导体封装的理想材料。

高级陶瓷

优势

先进陶瓷对确保关键部件的可靠性、效率和性能至关重要

高纯度

在超洁净环境中减少污染。

热稳定性

在高温条件下高效运行

电气性能

出色的绝缘性或可控导电性取决于材料。

耐化学性

可承受半导体工艺中使用的腐蚀性化学品。

耐磨性

延长磨损条件下部件的使用寿命。

未来发展方向

随着半导体技术向更高精度和更小尺寸发展,先进陶瓷材料也将继续发展

- 提高材料纯度,减少颗粒和污染物。

- 开发热导率更高、介电常数更低的新型陶瓷。

- 实现复杂陶瓷部件的精密加工技术。

常用材料

特点可用作氧化铍的替代品,不会产生有害健康的有毒气体,热膨胀系数与硅相似,因此适合高温应用。

特点卓越的机械性能、导热性和高温稳定性。纯度范围从 90% 到 99.8%。纯度较高的型号广泛应用于半导体行业。

特点它以出色的硬度和韧性著称,常用于高精度半导体加工设备的喷嘴和密封部件等关键部件。

特点具有电气绝缘性和高导热性的材料可在要求耐用性和精度的领域提供可靠的组件

常见问题

先进陶瓷为何广泛应用于半导体行业?

先进陶瓷具有出色的热稳定性、高纯度、电绝缘性和耐化学性,因此非常适合半导体制造中的高温、腐蚀和精密环境。此外,它们出色的机械强度和低热膨胀系数也确保了设备运行的可靠性和精确性。

氮化铝 (AlN) 陶瓷在半导体中有哪些典型应用?

氮化铝陶瓷具有高导热性和绝缘性,被广泛应用于芯片载体、散热基板和热管理元件。它们能有效减少热量损失,提高设备性能和使用寿命。

哪些先进陶瓷材料适合在腐蚀性环境中应用?

碳化硅(SiC)和氧化铝(Al₂O₃)是耐腐蚀性极强的陶瓷材料,可抵御半导体加工过程中的等离子体、强酸和强碱环境。它们常用于蚀刻设备部件和化学气相沉积 (CVD) 室。

如何评估陶瓷材料在高精度设备中的性能?

陶瓷材料性能评估通常包括以下指标:

热膨胀系数:决定材料在温度变化时的尺寸稳定性。

机械强度:确保高负载条件下的可靠性。

表面平整度和粗糙度:对光刻系统和晶片处理设备至关重要。

纯度和微观结构:影响颗粒污染和使用寿命。