Wafer steppers are core equipment in the field of modern semiconductor manufacturing. These instruments, worth tens of millions of dollars, can project nanoscale circuit patterns on silicon wafers. Their main workflows include light source emission, mask graphic imaging, objective lens focusing, and wafer stage (X-Y stage) precise alignment and step-and-repeat movement. The seemingly weak physical phenomenon of thermal expansion effect has become a basic challenge restricting lithography accuracy. When equipment components change size due to temperature changes, it will lead to alignment errors and wafer scrapping. Zerodur glass, a high-purity amorphous ceramic glass developed by SCHOTT of Germany, has become the core material of semiconductor lithography process due to its near-zero thermal expansion characteristics.

Key physical properties of Zerodur

| Performance Indicators | Numeric | Unit |

| Thermal expansion coefficient (0-50°C) | 0±0.007 | ×10⁻⁶/K |

| Density | 2.53 | g/cm³ |

| Young’s modulus | 9.1×10¹⁰ | Pa |

| Poisson’s ratio | 0.24 | – |

| Thermal conductivity (20°C) | 1.46 | W/(m·K) |

| Maximum operating temperature | 600 | °C |

Significance:

- Ensure sub-nanometer stability under temperature fluctuations

- Reduce inertia of moving parts and increase positioning speed

- Provide high-rigidity support platform

- Reduce the impact of multi-dimensional stress coupling

- Promote uniform temperature distribution and reduce thermal gradients

- Tolerate unexpected temperature rise during the process

Key Features

In addition to excellent thermal stability, Zerodur also has several key properties

- Three-dimensional uniformity: very few defects such as bubbles and streaks inside the material

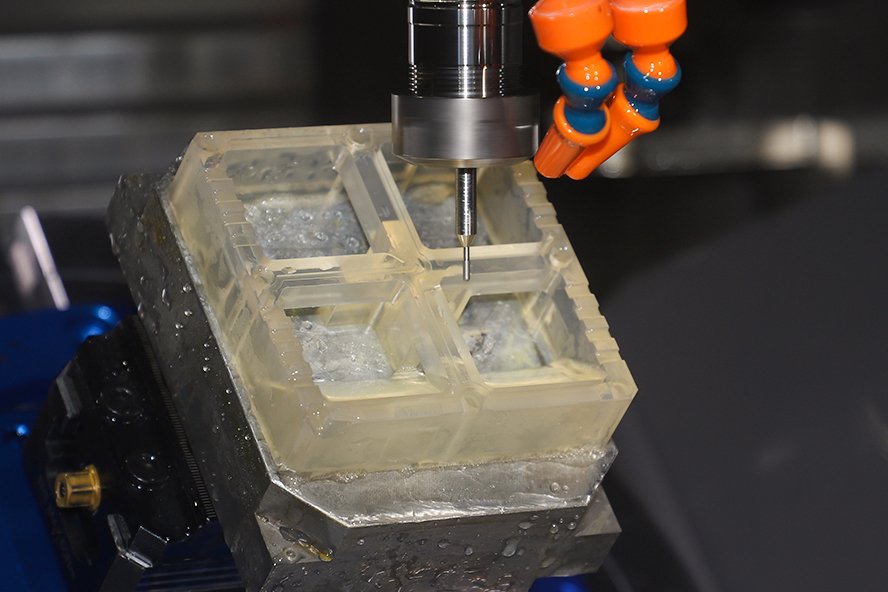

- Mechanical stability: fracture toughness of about 0.9 MPa·m¹/² and high bending strength, can be precisely processed into complex shapes

- Low helium permeability: This ability can ensure long-term dimensional stability in semiconductor equipment

- Surface treatment capabilities: can be polished to sub-nanometer surface roughness and can accept various optical coatings

Core Applications

Projection optical components: support bases for fixing and supporting multiple sets of precision optical lenses, beam splitters or refraction/reflection mirrors

Mask and wafer alignment system: mask carrier, wafer stage plate, alignment target plate

Wavefront correction: wavefront distortion compensation element, temperature gradient compensation plate

Contact Us

If you need customized optical components (such as Zerodur, ULE, fused silica, sapphire glass, etc.) and positioning platform solutions, please feel free to contact us. We have rich experience and sophisticated equipment for this.