In the demanding field of vacuum systems, every gram of material is crucial. Whether in semiconductor lithography, space optics, or quantum instruments, engineers are constantly striving for optimal design—choosing materials that are lightweight, have excellent thermal stability, and low outgassing rates. Lightweighting is not just about reducing weight, but also about ensuring a perfect balance of precision, thermal stability, and mechanical integrity in a vacuum environment.

Why Lightweight Design Matters in Vacuum Engineering

Reducing component mass in vacuum systems leads to a cascade of benefits:

Enhanced structural stability – lower mass minimizes gravitational sag and mechanical stress.

Improved dynamic response – lighter parts allow faster motion and vibration control.

Thermal uniformity – reduced thermal inertia enables faster stabilization during temperature cycling or bake-out.

Lower contamination risk – lightweight materials often require less structural support, minimizing the number of joints and fasteners that could outgas.

In precision systems—such as satellite payloads, metrology chambers, and laser resonators—these improvements translate directly into higher reliability, better optical alignment, and longer system lifetime.

Zerodur– Lightweight Precision with Thermal Zero

Schott AG’s Zerodur is a high-performance glass-ceramic known for its near-zero coefficient of thermal expansion. In addition to its excellent thermal properties, Zerodur excels in precision machining, allowing it to be machined into honeycomb, ribbed, or lightweight mirror-finish substrates—reducing weight by up to 70% while maintaining rigidity and optical flatness. This makes it an essential material for vacuum and cryogenic environments (learn more about Zerodur performance parameters and applications).

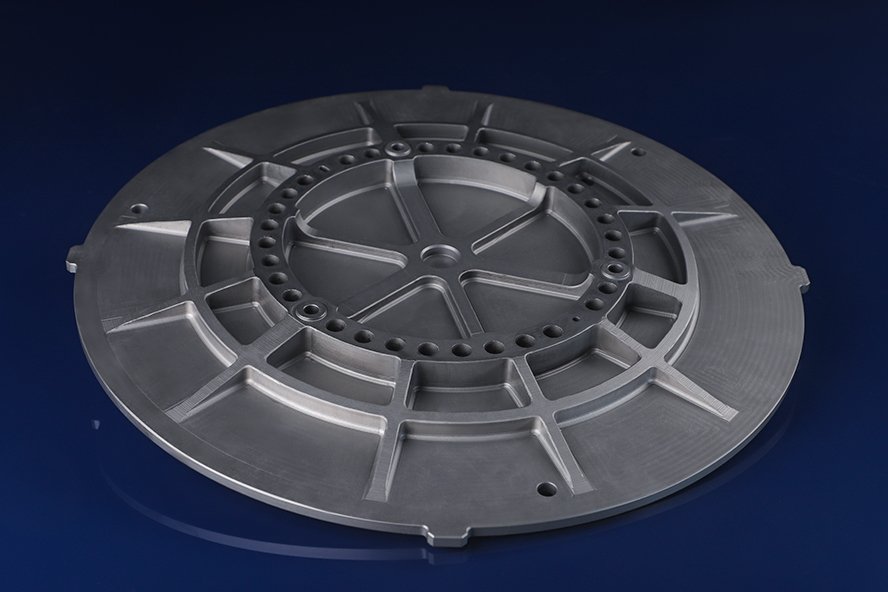

Silicon Carbide (SiC) – The Structural Backbone of Lightweight Design

Silicon carbide achieves a unique balance between high stiffness, low density, and excellent thermal efficiency, boasting the highest stiffness-to-weight ratio among all engineering materials. This makes it the preferred choice for applications requiring extremely high mechanical strength and thermal control. Significant weight reduction through sintering and CNC machining allows for the creation of large mirrors and vacuum structures that maintain both strength and quality control.

(Click to learn about the performance and applications of silicon carbide)

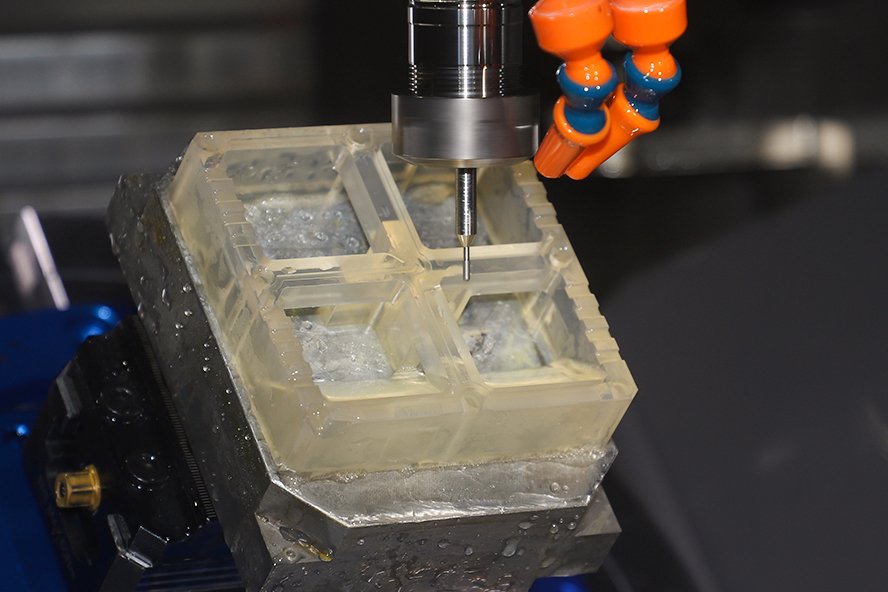

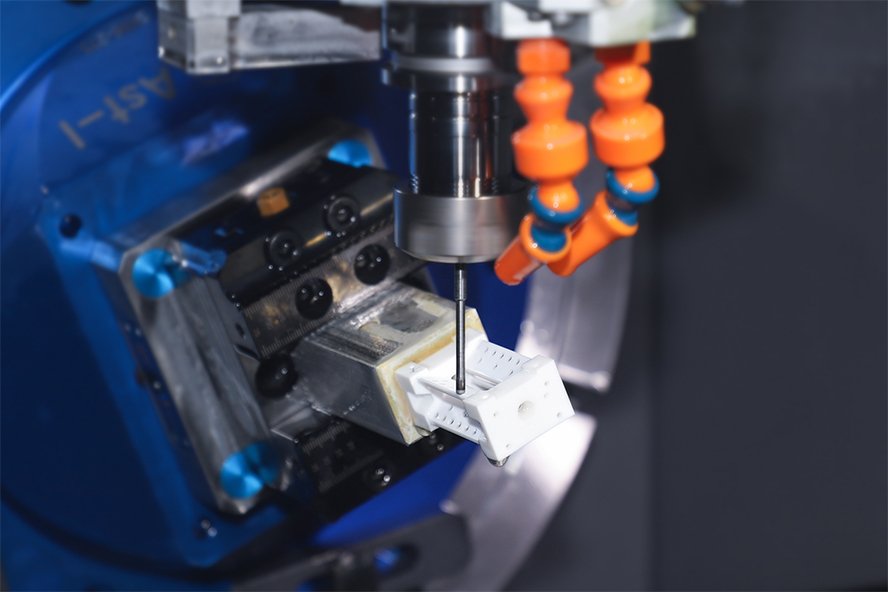

Macor– Machinable Glass Ceramic for Rapid Vacuum Prototyping

Developed by Corning Incorpor, Macor is a machinable glass-ceramic that provides an efficient solution for custom and prototyping applications. It enables the fabrication of complex micron-sized structures through high-precision machining, while also offering excellent electrical insulation, thermal stability, and low outgassing, making it suitable for ultra-high vacuum (UHV) environments. Its fast and flexible turnaround time makes it ideal for research and development and experimental setups. (Click to learn more about Macor’s performance and applications)

Contact Us

Looking for custom vacuum-compatible components or precision lightweight ceramics? Contact our experts today for assistance.

The Road Ahead – Integrating Multi-Material Lightweight Solutions

The future of vacuum systems lies in hybrid lightweight designs, combining the unique strengths of each material:

Zerodur for optical stability and ultra-flat precision

SiC for mechanical strength and thermal control

Macor for rapid prototyping and flexible design

As the vacuum industry continues to evolve—driven by quantum research, semiconductor miniaturization, and aerospace innovation—the ability to achieve extreme lightweight precision will define the next generation of high-performance systems.

Lightweight design is not just a mechanical goal—it is a core strategy for achieving higher accuracy, longer stability, and greater efficiency in the vacuum technologies of tomorrow.