Although both glass ceramics and advanced ceramics are inorganic non-metallic materials, they are essentially two different materials. Advanced ceramics are derived from sintered powders, and their microstructure is uneven and inherently porous, which limits their ultimate mechanical and thermal properties. In contrast, glass ceramics are complex engineering materials. In the field of superhard materials and high-end materials, exploring the essential differences between glass ceramics and advanced ceramics is of great significance for material selection, process design and performance optimization of your project. I will analyze them from the perspectives of microstructure, preparation process, application scenarios, and selection.

Differences in microstructure

The initial form of glass ceramics is amorphous glass. After controlled crystallization, micron-sized crystals grow in the matrix, and finally present a structure of coexistence of crystal phase + glass phase, which can greatly reduce the thermal expansion coefficient of the material, while improving the overall crack resistance and easy processing.

Advanced ceramics (such as oxides or carbides) are sintered by powder at high temperature. The grains are tightly bound by grain boundaries, the structure is dense but the anisotropy is more obvious. The dense structure makes it less likely to break, and the relative hardness is extremely high.

Preparation process difference

Glass ceramics

- Melting-quenching: forming uniform glass;

- Controlled crystallization: secondary heating, adding nucleating agents to promote uniform microcrystal precipitation;

- Shaping/finishing: turning and milling can be performed in the glassy or partially crystalline state

Advanced ceramics

- Powder preparation: ball milling of high-purity oxides/nitrides/carbides;

- Forming: dry pressing, isostatic pressing, grouting, thin film coating, 3D printing;

- Sintering: atmospheric pressure sintering, hot pressing, gas pressure sintering or SPS;

- Post-processing: using precision methods such as diamond grinding and laser processing

Application Scenario

| Industry | Glass ceramics | Advanced ceramics |

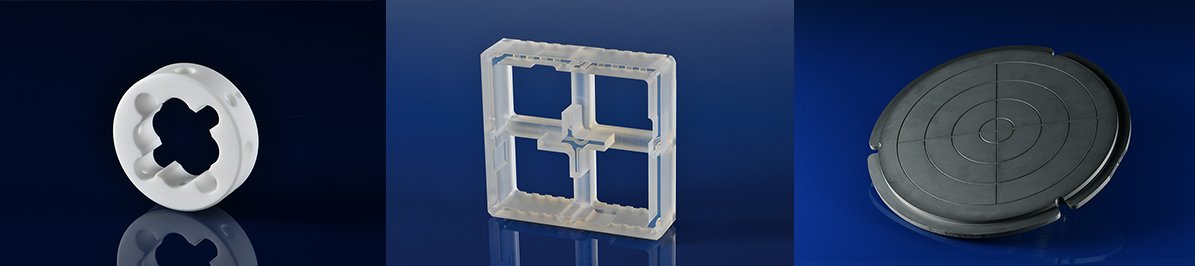

| Semiconductor & Lithography | Low expansion optical tables, mask substrates (Zerodur) | Thermal conductive plates, clamping arms, vacuum suction cups, etc. |

| Aerospace | Stable mirror mounts, satellite thermal control structures, laser gyroscope cavities | Si₃N₄ high-temperature bearings, SiC reflectors |

| Precision Instruments | Interferometer brackets, ion trap brackets | Silicon nitride rotors, ceramic gauge bases |

| Medical & Biotechnology | X-ray transparent platforms, human implants | Zirconium oxide implants, medical infusion pumps |

Selection Guide

Need low thermal expansion and good machinability → Glass ceramics

Precision optics, complex shaped cavities, fast prototyping.

Pursue extreme hardness/wear resistance, functionality (piezoelectric, thermal conductivity, insulation) → Advanced ceramics

High-speed/high-temperature conditions, electronic packaging, sensor actuators, etc.

Cost & batch factors

Glass ceramics have high initial melting costs, but cheap post-processing;

Advanced ceramics have long sintering cycles and expensive post-processing, but long life and extreme performance.

Contact Us

Let us take some of the work off your shoulders! Order superhard material machining services from Jundro Ceramics and experience the advantages firsthand: one-on-one engineering support, a single point of contact, highly competitive pricing, on-time delivery, and quality control.