Showerhead, also known as a gas distribution plate or gas shower plate, is a gas distribution component used in semiconductor processes such as PVD, CVD, and etching. Its core function is to uniformly distribute process gases into the reaction chamber, enabling high-quality thin film deposition, etching, or plasma reactions, thereby improving production efficiency and product quality.

Applicable Equipment

CVD

PECVD

PVD

Plasma Etchers

ALD

Core Functions and Roles

1. Control of Gas Distribution and Uniformity

The primary role of the showerhead is to accurately distribute process gases onto the wafer surface.

During wafer processing, the showerhead surface is densely populated with micro-holes (hole diameter: 0.2–6 mm). Through a large number of precision micro-holes, gases are delivered in a uniform and controllable manner, ensuring consistent thin film deposition rates, etching rates, and overall process uniformity across the wafer.

2. Improvement of Film Quality and Yield

Precise gas distribution → Uniform film thickness

Uniform reaction environment → Reduced defect density

Optimized hole diameter & pattern → Enhanced process stability

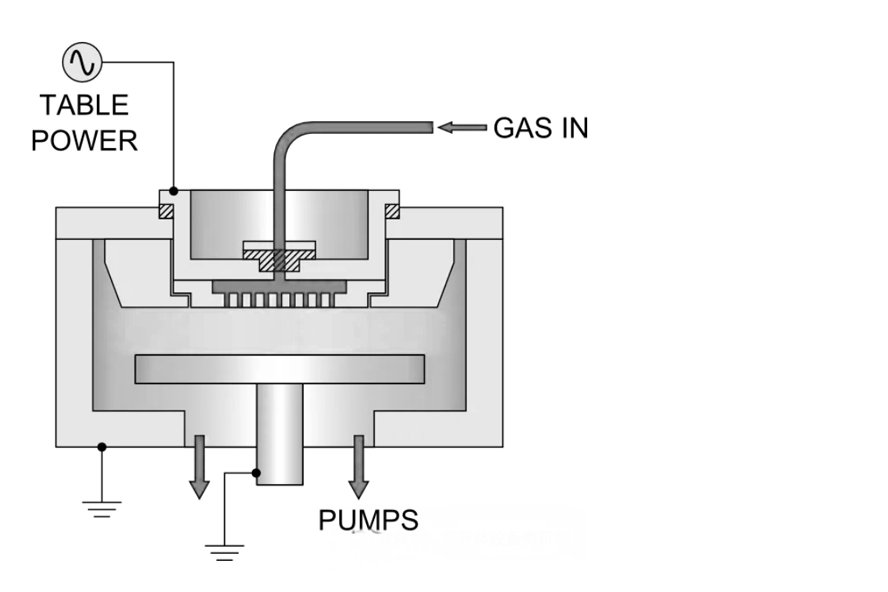

3. Function as a Plasma Electrode / Reaction Field Structure

In plasma-assisted processes (such as PECVD and dry etching), the showerhead often serves as an electrode.

When combined with an RF power source, it helps generate a uniform plasma field, thereby improving deposition or etching uniformity.

Basic Structure

A showerhead typically consists of:

Face Plate / Top Plate

A large number of micro-holes are evenly distributed on the surface for gas injection.

Back Plate / Support Structure

Connected to the gas supply plenum, ensuring uniform gas pressure across all holes.

Sealing and Connection Components

Maintain vacuum integrity inside the chamber and support easy disassembly and maintenance.

Material Selection

| Material | Key Advantages | Typical Applications |

| Metals (Al, SS, Ni) | High strength, good thermal conductivity | Etching, PVD |

| High-Purity Quartz | Low impurities, high thermal stability | CVD, PECVD |

| CVD SiC | Excellent corrosion resistance, high-temp stability | High-temp CVD |

| High-Purity Ceramics / Single Crystal | Low contamination, corrosion resistant | Advanced processes |

Importance of Showerhead in Semiconductor Manufacturing

📌 Core gas distribution component in semiconductor fabrication

📌 Determines thin film deposition / etching quality and process uniformity

📌 High technical complexity → Requires high-precision machining and advanced materials

📌 Directly linked to equipment performance → Impacts yield and operating cost

SiC / Quartz Showerhead Manufacturer

Jundro Ceramics is a professional manufacturer specializing in high-precision silicon carbide (SiC) and quartz showerhead components for semiconductor processing equipment. With advanced manufacturing capabilities and strict quality control, we provide reliable, high-performance components designed to meet the demanding requirements of semiconductor fabrication processes.