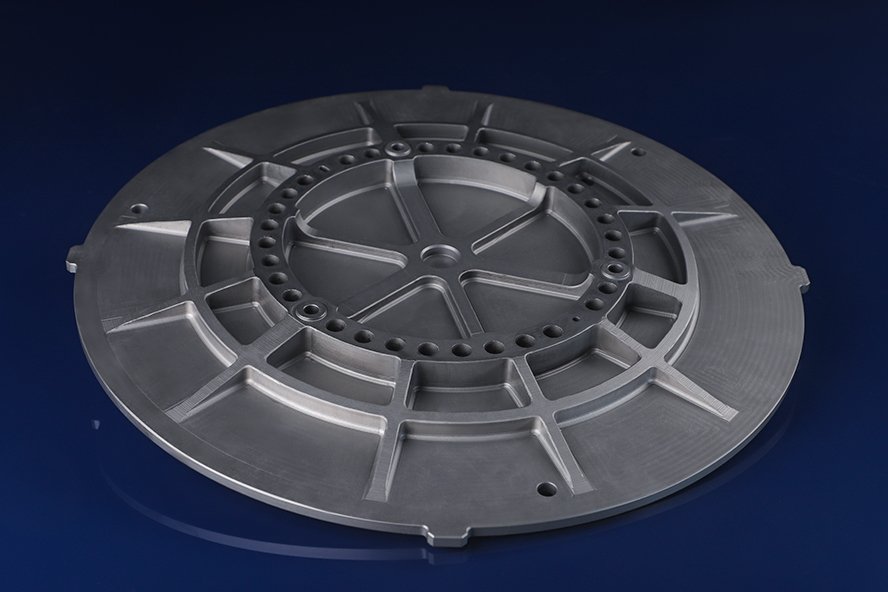

SIC Ceramic Chuck

High hardness, high thermal conductivity, low thermal expansion coefficient

Silicon Carbide Ceramic Chuck is usually used for vacuum adsorption, electrostatic adsorption or mechanical clamping of wafers

| Product | SlC Ceramic Chuck |

| Material | Silicon carbide |

| size | Φ310*20 |

SIC Ceramic Advantages

✅ Extremely low thermal expansion coefficient

✅ High thermal conductivity of 120–200 W/m·K

✅ Mohs hardness of 9.2, second only to diamond and cubic boron nitride

✅ Excellent chemical stability, suitable for cleanroom and vacuum chamber environments

✅ Surface can be processed by high-precision grinding and polishing

Applications

✅ Semiconductor wafer processing (e.g., CVD, etching, CMP)

✅ Optical glass processing and inspection

✅ Micromachining platform

✅ Laser processing platform

✅ Ultra-precision machining and measurement systems

Customizable Machining Services

High-performance SiC ceramic chucks place extremely high demands on manufacturers’ material control and precision machining capabilities. Our company boasts:

5-axis CNC equipment and ultra-precision polishing equipment

Surface finish accuracy reaches Ra 0.005 μm, with a flatness of < 1 μm

We provide a one-stop solution from structural design, finishing, to surface polishing.

Whether it’s custom-shaped fixtures or other parts, we offer stable and reliable SiC ceramic machining services.

Contact us via form

Not sure which ceramic material is suitable for your application? Contact our experts for assistance