Silicon Carbide(SiC/SiSiC)

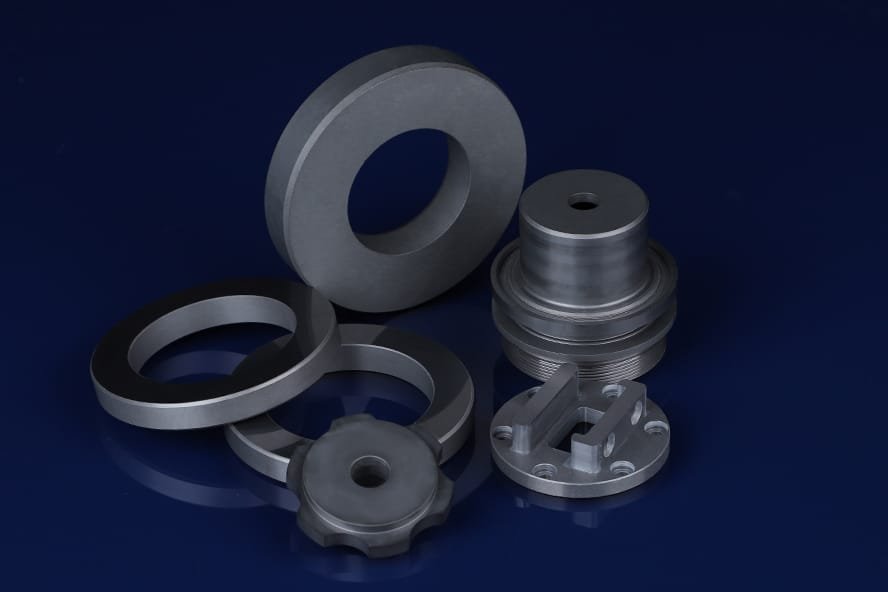

Silicon carbide (SiC) is one of the hardest ceramic materials, just after diamond. It stands out for its excellent wear resistance and heat dissipation, making it ideal for use in a wide range of industries, from electronics and automotive to aerospace and industrial machinery. SiC remains stable across a broad temperature range and resists thermal deformation, which adds to its reliability in tough conditions. It also boasts low thermal expansion, great thermal conductivity, and impressive resistance to acids and alkalis. The two main types, SSiC (sintered silicon carbide) and SiSiC (silicon infiltrated silicon carbide), are especially suited for producing large, complex components, offering outstanding performance where durability and precision are essential.

(SiC/SiSiC) Advantages

- Good gliding properties

- Non-toxic and environmentally safe

- Hardness second only to diamond

- Excellent high-temperature resistance

- High Young’s modulus (380 to 430 GPa)

- Excellent thermal shock resistance (ΔT = 1,100 K)

- Corrosion and wear resistant even at high temperatures

- Maintains high strength under both high and low temperature conditions

(SiC/SiSiC) Applications

- High-temperature and high-voltage power semiconductor devices

- Wear-resistant mechanical seals

- Heat exchangers

- High-temperature sensors

- Optical reflectors

- SiC ceramic bearings

- Energy technology components

- Pipeline system components

- Semiconductor vacuum chuck, ceramic chuck

- Refractory linings for high-temperature environments

Material Properties

| Property | Unit | Silicon Carbide |

| Density | g/cm³ | 3.15 |

| Vickers Hardness | Hv0.5 | 2650 |

| Bending Strength | MPa | 450 |

| Compressive Strength | MPa | 2650 |

| Elastic Modulus | GPa | 430 |

| Toughness | MPa·m¹/² | 4 |

| Poisson’s Ratio | – | 0.14 |

| Young’s Modulus | GPa | 430 |

| Purity of Silicon Carbide | % | 99 |

Thermal Properties

| Property | Unit | Silicon Carbide |

| Thermal Conductivity @ 25°C | W/mK | 110 |

| Melting Point | °C | 2800 |

| Specific Heat Capacity | J/gK | 0.8 |

| Linear Expansion Coefficient | 10⁻⁶/K | 4 |

Electrical Properties

| Property | Unit | Silicon Carbide |

| Dielectric Constant (1 MHz) | – | 10 |

| Breakdown Voltage | V/cm | 1×10⁶ |

| Dielectric Loss (1 MHz) | – | 0.001 |

| Resistivity | Ω·cm | 10⁷–10⁹ |

Note: This value is for reference only and may vary slightly depending on the batch conditions.

Silicon Carbide Machining

Silicon carbide (SiC) machining is a challenging yet essential process for producing high-performance components used in extreme environments. Known for its exceptional hardness, high thermal conductivity, and wear resistance, SiC is commonly used in industries such as aerospace, automotive, electronics, and energy. Machining SiC requires specialized tools and techniques, as the material’s hardness and brittleness make it difficult to cut and shape using traditional methods. Precision grinding, diamond tooling, and laser machining are often employed to achieve the desired dimensions and surface finishes. Advanced techniques like waterjet cutting and ultrasonic machining can also be used for complex geometries. Proper machining of silicon carbide ensures the production of durable, high-quality parts that maintain stability in high-temperature, high-pressure, and chemically aggressive environments.

Prototype Machining Video

This is a ceramic prototype machining video from Jundro

Frequently Asked Questions

The friction coefficient of SiC typically ranges from 0.15–0.25 in dry conditions and 0.05–0.10 with lubrication, depending on surface finish, load and environment. Polished SiC shows the lowest friction and excellent wear resistance, making it ideal for mechanical seals and sliding components.

Yes. SiC can be polished to a true mirror finish, typically achieving Ra ≤ 0.001 using fine diamond grinding and chemical–mechanical polishing.

SiC has a wide bandgap of ~3.2 eV, slightly lower than GaN (~3.4 eV), but it offers unique advantages:

Higher thermal conductivity (~120–200 W/m·K vs ~130 for GaN)

Higher breakdown voltage

Excellent thermal stability for high-power devices

Better substrate availability and cost compared to GaN-on-SiC

This makes SiC ideal for high-power, high-temperature, and high-voltage applications such as EV inverters, power modules, and industrial power systems.

SiC is widely used for mechanical seals because it offers:

Very high hardness and superior wear resistance

Low friction coefficient

Excellent chemical and corrosion resistance

High thermal conductivity for heat dissipation

Dimensional stability under temperature and pressure

These properties ensure long service life, low leakage, and reliable performance in pumps, compressors, and chemical processing equipment.

SSiC (Sintered SiC): Highest strength, purity, hardness, and corrosion resistance. Best for mechanical seals, semiconductor parts, and high-wear components.

RBSiC (Reaction-Bonded SiC): Lower cost, easier to form complex shapes, but slightly lower strength and some residual Si. Good for structural parts and large components.

CVD SiC: Ultra-pure, extremely dense, mirror-polish capable, ideal for semiconductor, optical, and vacuum applications. Highest performance and cost.

How to choose:

Wear & sealing: SSiC

Complex shapes & lower cost: RBSiC

Optical/semiconductor: CVD SiC

High-temperature structural: SSiC

Yes. SiC components can be produced in small batches using diamond grinding, ultrasonic machining, or laser processing.

MOQ: Typically 1 pieces for prototypes, depending on geometry.

Lead Time: Usually 2–4 weeks for small batches; complex parts may require longer.

Professional machining shops like Jundro Ceramic provide low-volume precision SiC manufacturing with full QC reports and material traceability.