溶融石英の定義

溶融石英/溶融シリカは、高純度二酸化ケイ素を溶融・急冷して得られる非晶質ガラスです。極めて低い熱膨張係数、優れた光学透過率(紫外-可視-赤外領域をカバー)、高い耐熱性、強い耐薬品性腐食性が特徴です。これらの特性により、半導体装置部品、航空宇宙用センサー、真空チャンバーなどの要求の厳しい用途で重要な材料となっている。

石英部品加工能力

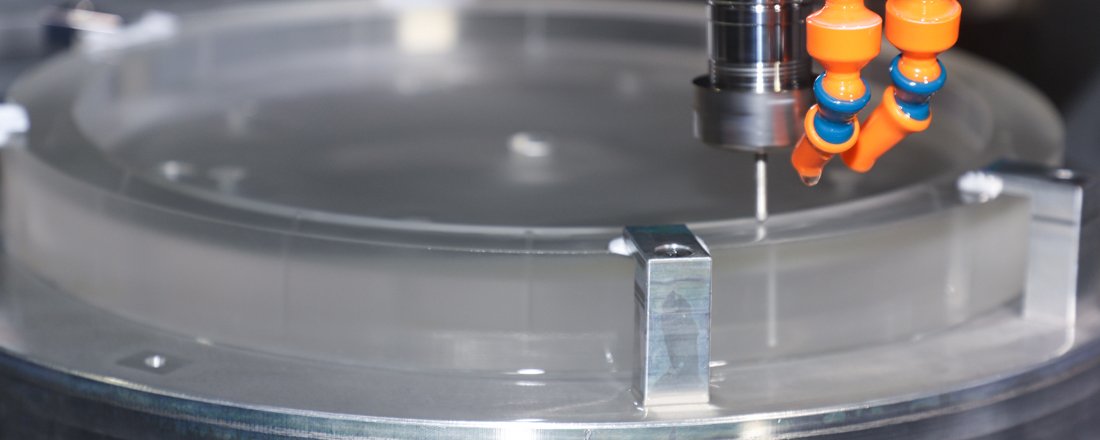

機械加工設備:多軸CNC精密フライス加工、レーザー切断&マーキング、超精密平面研削&研磨、超音波洗浄、クリーンルーム梱包。

高精度能力:

複雑な形状: ±0.01 mmまでの公差

円筒/シャフト部品: ±0.001 mmまでの公差

表面平坦度:最大0.001 mm

光学平面度:最大1/20λ(波長による)

マイクロホール:最小直径0.1mm(公差±0.01mm)

表面粗さ構造部品はRa 0.01μm、光学部品はRa 0.002μm

表面処理:研磨、光学コーティング

検査装置:三次元測定機(CMM)、干渉計、プロフィロメーター、表面粗さ計、真円度計など。

品質システム:ISO 9001およびISO 14001、ISO 13485認証取得。検査報告書提供(FAR/FAI、測定報告書、表面品質報告書)。

加工工程の流れ(図面から完成品まで)

要件確認とDFxレビュー:2D/3D図面、材料仕様、重要公差、バッチサイズ、納期を受け取り、加工性評価を行います。設計最適化の提案(例:穴緩衝、最小肉厚、支持構造)を行います。

材料の準備:グレードに応じた溶融石英プレート/ロッド/プリフォームを、完全なバッチ記録と証明書とともに調達する。

粗加工:ノコギリ切断とCNC粗加工により、ネットに近い形状に仕上げる。

熱応力アニール(必要な場合):残留加工応力を緩和し、後工程でのクラックを防止する。

精密機械加工:多軸加工、微細穴、角穴、その他の微細形状。

超精密研削・研磨:要求される平坦度と光学グレードの表面粗さを達成する。

クリーニング&コーティング(必要な場合):超音波/純水洗浄、真空乾燥、反射防止コーティングや保護コーティングの前処理。

最終検査と梱包:品質計画に従って検査報告書を発行。コンポーネントは、バッチラベルと検査ラベルを貼った静電気防止クリーンルーム包装で梱包されます。

共通仕様と実現可能性

最小フィーチャーサイズ:微細穴は0.1mmから、サンプル要求の評価によりそれ以下の形状も可能。

寸法公差複雑な表面では±0.01mm、シャフトや円筒部品では±0.001mm。

平坦度 / 光学的要件:構造部品の平面度は0.001mm、光学的平面度は1/20λまで。

表面粗さ:構造部品のRaは0.01μm、光学部品のRaは0.002μm。

最大加工サイズ:材料ブランクと設備容量に応じて調整可能 - 確認のための図面を歓迎します。