現代のプラズマおよびイオンソース技術では、極端な電界、熱サイクル、および高真空環境に耐えることができる材料によって信頼性が左右されます。すべてのエンジニアリングセラミックスの中で、アルミナ(Al₂O₃)は、機械的強度、電気絶縁性、化学的安定性のバランスがとれており、RFおよびDCプラズマアプリケーションに好ましい選択であり続けています。.

アルミナがイオン源やプラズマ源に最適な理由

アルミナ・セラミックスは、プラズマ・ベースのシステムに不可欠ないくつかの重要な利点を兼ね備えている:

優れた絶縁耐力 高電圧およびRFアプリケーション用

高い熱安定性, 1600℃まで構造と断熱性を維持

真空適合性 - 極めて低いアウトガスとコンタミネーション

プラズマ侵食に対する耐性 およびAr、O₂、CF₄などの反応性ガス。

精密加工性 複雑な形状や微細な公差に対応

これらの特性により、アルミナは、以下の温度で動作するRFプラズマ源に最適である。 13.56 MHz やイオンビームシステムでは、正確な電気絶縁と真空シーリングが不可欠です。.

イオン源およびプラズマ源に使用される一般的なアルミナ成分

カップ型排出室

プラズマ閉じ込め空洞として使用。.

カソード、アノード、取り出し電極間を電気的に絶縁する。.

RF真空ウインドウ

プラズマチャンバーに13.56MHzのRF電力を送信する。.

真空圧と温度サイクルに耐える設計。.

絶縁リングとスペーサー

金属電極と構造部品を分離する。.

高電圧動作下でも機械的アライメントを維持する。.

ガスフィードスルー・インシュレーターとサポートチューブ

真空の完全性を維持しながら、ガスや冷却ラインを導入するために使用される。.

プラズマシステム、イオンソース、高真空関連機器の研究室およびOEMメーカー向けアルミナ部品のカスタム加工。.

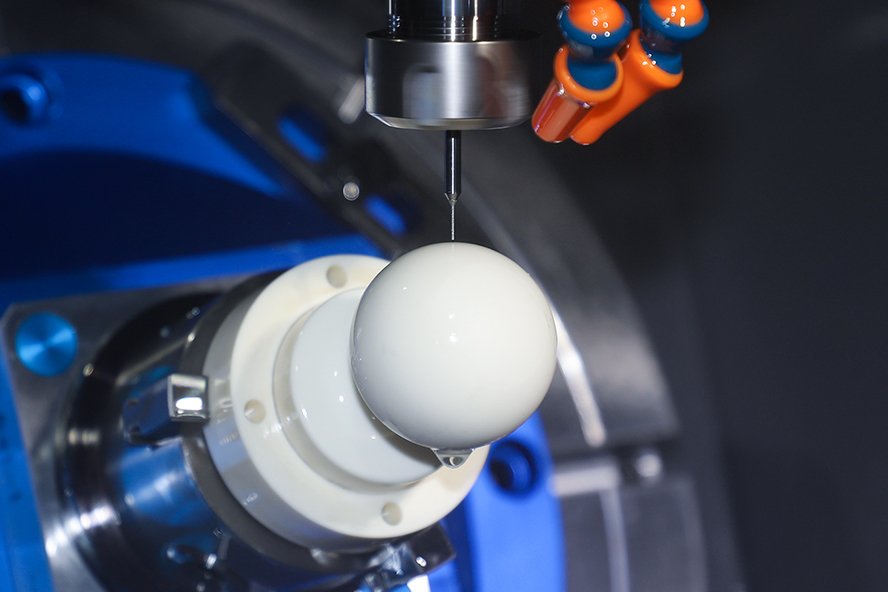

精密加工能力

ジュンドロ・セラミックスでは 3軸、4軸、5軸CNCマシニングセンター を達成できる:

寸法公差: ±0.01 mm

表面粗さ: Ra 0.01 μm

平坦さ: 0.001mmまで

複雑な内部および外部形状

各パーツはISO9001の厳格な品質管理の下で製造され、必要に応じてカスタマイズすることができます。 図面または3D CADファイル(STEP、STP、PDF).

対応アプリケーション

RFプラズマ発生装置およびエッチング装置

イオンおよび中性ビーム源

加速器と核融合の研究

半導体蒸着・スパッタリング装置

宇宙推進とプラズマ診断

我々は、以下のようなアルミナ部品の供給に成功している。 カップ型イオン源チャンバー, 国際的な研究機関やプラズマ装置メーカーに。.