What is Zero Porosity Macor Glass Ceramics?

Macor glass-ceramic is a unique machinable glass-ceramic developed by Corning, which consists of a glass matrix and a microcrystalline phase. Its main features are machinability and zero porosity. Its microcrystals are evenly distributed in the glass matrix, filling most of the potential micropores. This makes the material almost completely dense in microstructure. In addition, the material also has excellent mechanical strength, excellent insulation and dimensional stability.

Core Advantages

Mechanical Properties

- Zero porosity ensures a material with uniform density capable of withstanding high mechanical stresses.

- High machinability, can be directly cut, drilled and polished with standard machining tools, without expensive tools

Thermal roperties

- Operating temperature up to 800°C, can withstand 1000°C for a short time

- The coefficient of thermal expansion matches that of most metals and glasses, facilitating bonding with other materials.

Electrical Properties

- Excellent electrical insulation, high resistivity, and stable performance even in high temperature environments.

Advantages of Zero Porosity

- Non-hygroscopic, stable in extreme environments such as vacuum or high humidity.

- Surface can be polished to an extremely fine finish (0.5 µin) for optical and vacuum sealing applications.

Comparison With Another Machinable Ceramic

Different engineering applications require different material properties. You can choose materials according to your actual needs, or contact our experts to provide you with appropriate suggestions.

Macor glass ceramic Application

Medical artificial eye bracket

Macor glass ceramics are widely used in the medical field. The material is non-toxic, odorless has good biocompatibility, can remain stable in the physiological environment of the human body, and its excellent performance can also support various forces during surgery to ensure the safety of surgery.

Experimental fixed support

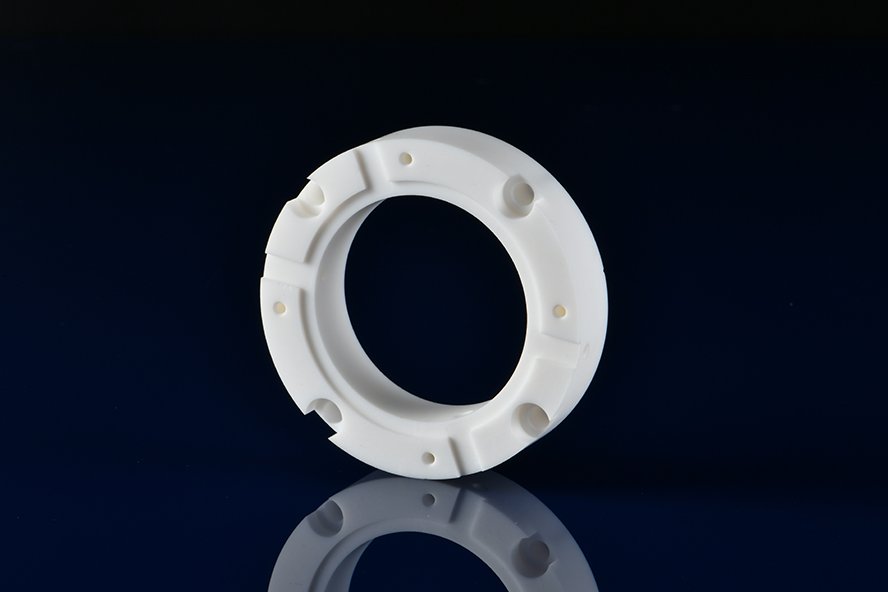

Many experimental equipment will use support components made of macor, such as quadrupole mass spectrometers, ion trap brackets, and as shown in the picture, to provide stable support components for test equipment

Aerospace components

Macor is usually used in aerospace to make thermal insulation gaskets, vacuum sealing components, etc. Its zero porosity can ensure that there will be no material leakage and degradation in a vacuum environment. For example, NASA also uses this material in aircraft hinges, doors and windows.

Semiconductor Manufacturing

Macor can also be seen in the semiconductor industry, such as mechanical parts responsible for wafer transfer tasks, and high-purity customized components, such as vacuum chamber components, wafer inspection fixtures, etching equipment support components, etc.

A small method to test porosity

The non-porosity of a material can be quickly tested by soaking it in oil-based dyes or industrial inks. This is done by soaking the material and then observing the surface with a microscope to see if there is any sign of color residue or penetration. This is a simple and reliable test for a wide range of materials including Macor and other ceramics.

We have created a YouTube video on Macor and Alumina that shows how to do an initial verification with this method. This method is suitable for quickly evaluating the density and non-porosity of a material in a laboratory or production environment.

How to choose a supplier

Macor glass ceramics have become an ideal material for many industries, with unique performance advantages. Jundro Ceramics has accumulated many years of experience in macor processing and has maintained good cooperation with many well-known universities and laboratories. We can provide high-quality macor rods, blocks, tubes, and customized components. If your project requires it, please feel free to contact our experts.