Zerodur zero-expansion glass-ceramic has long been recognized as an outstanding material in the industrial market, with well-established application areas. In the field of photolithography, it is widely used in critical components such as reticle blank substrates, lithography stage bases, and mirrors and frames in stepper alignment and positioning systems. Its thermal properties can be customized for specific temperatures (click here to view Zerodur properties), offering virtually negligible thermal deformation, which meets the stringent requirements of modern lithography processes.

Material Advantages

- Ultra-low thermal expansion coefficient (0±0.02 × 10⁻⁶ K⁻¹)

- Extremely high dimensional stability, able to maintain consistency for a long time at the 1nm level

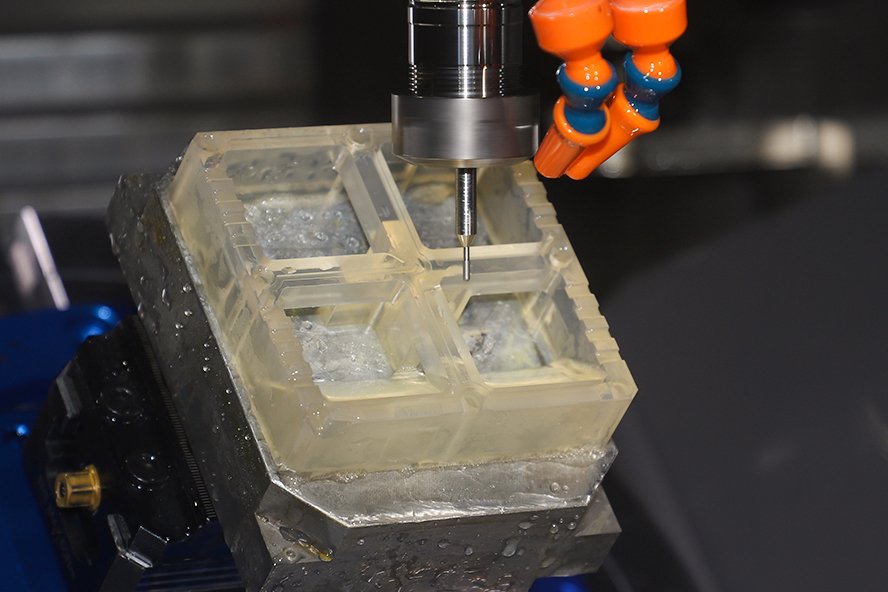

- Can be processed and polished with high precision, achieving a flatness accuracy of 1/20λ

- Excellent chemical properties, strong tolerance to common etching and cleaning chemicals

Microlithography Application

- Reticle Blank substrate

- EUV lithography machine substrate

- Zerodur support frame

- Interferometer mirror, plane mirror, double prism, etc.

- Alignment system components

Summarize

Zerodur has become a key material in the field of microlithography due to its ultra-low CTE and high dimensional stability. Jundro Ceramics is a high-quality manufacturer specializing in the processing of Zerodur. It has rich experience in machining substrates, reflectors, measuring mirrors, etc. and can perfectly meet your requirements. Please feel free to contact our experts. We are happy to provide you with services.