In the semiconductor field, etching equipment is a critical process in semiconductor manufacturing. Common etching methods include dry etching, plasma etching, reactive ion etching, etc. In these etching equipment, some high temperature resistant, corrosion resistant, and insulating materials are usually used, such as ceramic materials (aluminum oxide (Al₂O₃), aluminum nitride (AlN), silicon nitride (Si₃N₄), silicon carbide (SiC), etc.). These ceramic materials each have their own characteristics and different applications in etching equipment. Next, I will introduce the role of these ceramic materials in it.

1. Lining of reaction chamber

Material: Al₂O₃, AlN

Function: Reduce metal contamination and protect the chamber from plasma and corrosive gas erosion

2. Electrostatic Chuck (ESC)

Material: AlN, Al₂O₃, SiC

Function: Fix the wafer by electrostatic force to prevent wafer deviation, and have thermal conductivity and insulation

3. Gas Distribution Plate

Material: Al₂O₃, Quartz, Si₃N₄

Function: Distribute reaction gas into the chamber to ensure uniform etching

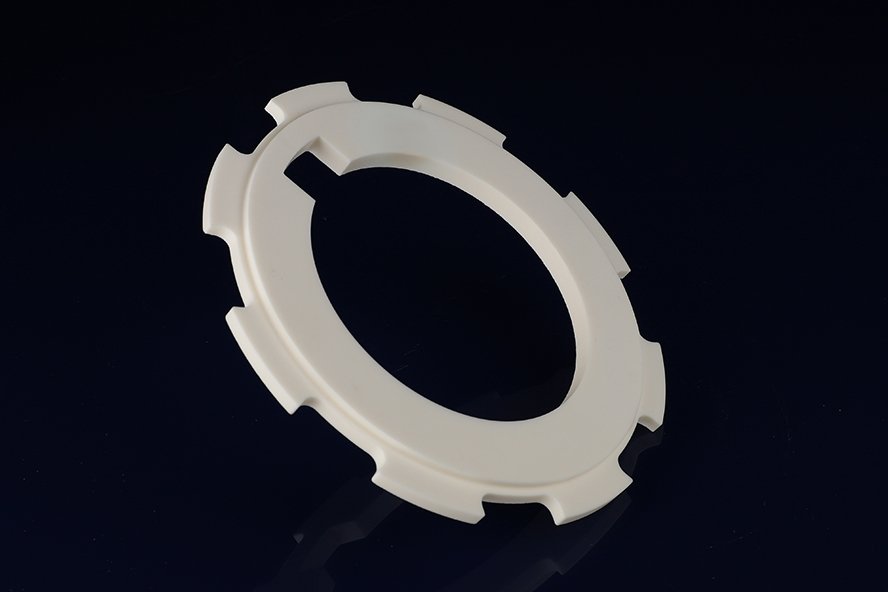

4. Insulation Ring/Isolation Ring

Material: SiC, Al₂O₃

Function: Isolate the RF electrode and the chamber to avoid discharge or short circuit

5. Focus Ring

Material: Al₂O₃, SiC, Quartz

Function: Protect the edge of the wafer from excessive etching

6. Wafer Support/Plate

Material: AlN, SiC, Al₂O₃

Function: used to carry wafers, with both thermal conductivity and insulation properties

7.Viewport

Material: Quartz SiO₂, sapphire (Al₂O₃ single crystal)

Function: used for optical monitoring window, high temperature resistance and good light transmittance, to avoid plasma damage

8.Heating element

Material: Si₃N₄, SiC

Function: provide uniform heating in high temperature etching, ensure reaction efficiency, and avoid metal contamination

Advantages of ceramic materials in etching

Quartz sapphire parts are of high purity and do not contain metal impurities, which can avoid pollution.

Strong resistance to corrosive gases, can resist corrosion such as Cl₂ and F-based gases for a long time, and extend the life of parts.

Thermal conductivity/insulation can avoid discharge or short circuit, and the excellent thermal conductivity of ceramic materials can ensure the temperature control accuracy of wafer process.

High mechanical strength, can accurately process complex shapes, and adapt to a variety of etching process environments

Semiconductor equipment ceramic parts manufacturer

We are a professional ceramic parts manufacturer with high-precision five-axis machining equipment that can achieve ultra-high precision and can process irregular shapes, curved surfaces, and other irregular structural components.

If you need customized ceramic parts for semiconductor equipment, please feel free to contact our experts to provide you with services