窒化アルミニウムの特性と工学的応用

窒化アルミニウム(AlN) は非常に高い熱伝導率、優れた電気絶縁性、低熱膨張係数、優れた高温耐性、優れた化学的安定性により、ハイエンドのエンジニアリング分野で広く使用されている優れた性能を持つ先進的なセラミック材料です。硝酸アルミニウムとは異なり、窒化アルミニウムは化学式の酸化状態が-3の窒素の化合物であり、硝酸アルミニウムは硝酸塩の塩またはエステル体である。窒化アルミニウムは六方晶系のウルツ鉱型結晶構造を持ち、独特の物理的・化学的特性を有しています。

窒化アルミニウムのエンジニアリング用途

1.ハイパワー・エレクトロニクス・パッケージングと基板

アプリケーション・シナリオ:IGBTモジュール、RFパワーデバイス、高周波マイクロ波部品。

窒化アルミニウムが使われる理由

- 高い熱伝導性:効率的に熱を放散し、電子部品を保護します。

- 熱膨張マッチング:シリコンチップをマッチングさせ、機械的ストレスを低減。

- 優れた絶縁性:高電力条件下での電気的信頼性を確保。

エンジニアリング・アプリケーション

- パワー半導体デバイス基板

- 5G通信用高周波パッケージング

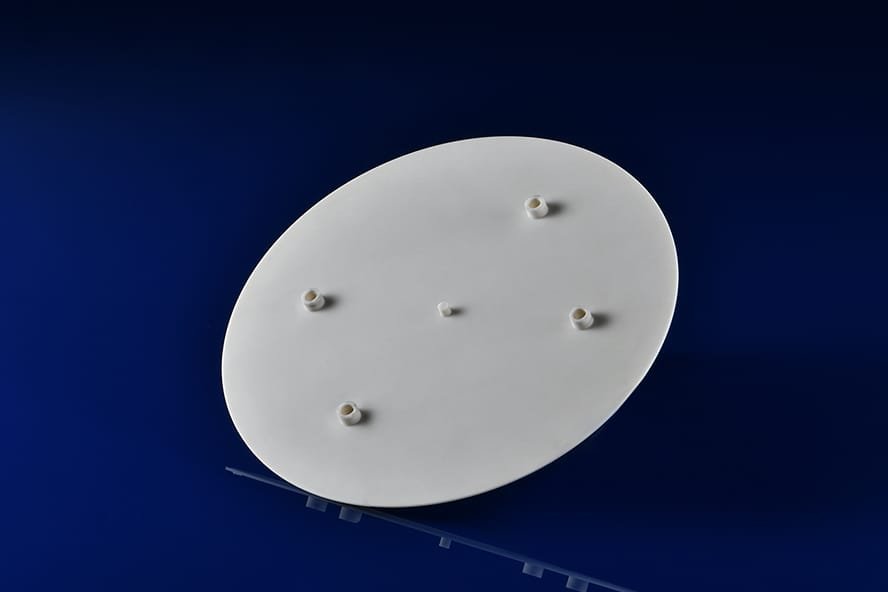

2.半導体製造部品

アプリケーション・シナリオ:半導体製造におけるウェーハサポート部品と高温焼結プラットフォーム

窒化アルミニウムが使われる理由:

- 高温安定性:酸化することなく高温プロセスに耐える。

- 熱膨張マッチング:シリコンウェーハへの熱ダメージを最小限に抑えます。

エンジニアリング・アプリケーション

- 半導体プロセスにおけるウェハーキャリアと基材

- 高温フィクスチャーとサポート構造

3.マイクロ波デバイスとRFシステム

アプリケーション・シナリオマイクロ波およびRFコンポーネントの絶縁基板および熱管理。

窒化アルミニウムが使われる理由:

- 低誘電率・高絶縁:安定した高周波信号伝送を確保

- 高い熱伝導性:熱を効果的に放散し、RFシステムの信頼性を維持します。

エンジニアリング・アプリケーション

- 5G通信モジュール用マイクロ波基板

- RFアンプ用パッケージ基板

4.レーザーと光デバイスのパッケージング

アプリケーション・シナリオ:高出力レーザーと光学部品の熱管理と構造パッケージング

窒化アルミニウムが使われる理由:

- 優れた熱管理:効果的な熱除去により、安定したレーザー動作を維持します。

- 電気絶縁性と機械的安定性:高電圧、高温条件下でも高い信頼性を確保。

エンジニアリング・アプリケーション

- 高出力レーザー用放熱部品

- 光デバイス用構造部品

5.航空宇宙システムにおける熱管理

アプリケーション・シナリオ:衛星用電子機器や高温構造部品の熱制御部品。

窒化アルミニウムが使われる理由:

- 高い熱伝導率と軽量構造:放熱と軽量化に不可欠。

- 高温と耐食性:真空および極端な熱サイクルに適しています。

エンジニアリング・アプリケーション

- 衛星電力システムにおける熱基板

- 航空宇宙用センサーおよびコントローラー用高温ベース

将来のエンジニアリング用途における窒化アルミニウムの可能性

科学技術の急速な発展に伴い、新エネルギー自動車、5G通信、ハイパワー電子機器などの最先端分野における窒化アルミニウムの需要は、今後も増加し続けるだろう。

材料の革新:窒化アルミニウムをベースとする複合材料は、機械的特性と熱管理効果をさらに向上させることが期待される。

コストの最適化:製造プロセスが成熟するにつれて、窒化アルミニウムのコストは低下し、大規模な応用が促進されると予想される。

窒化アルミニウムのエンジニアリング用途の概要

窒化アルミニウムのエンジニアリング用途の概要

窒化アルミニウムは、高い熱伝導性、電気絶縁性、高強度、シリコンとの熱膨張係数の一致などの利点により、半導体パッケージング、光学機器、航空宇宙、パワーエレクトロニクスにおいて重要な役割を果たしている。窒化アルミニウムをコア材料として選択することで、放熱、電気絶縁、熱応力管理などの工学的問題を解決することができます。窒化アルミニウムは、ハイエンドのエンジニアリング用途において、かけがえのない材料のひとつです。

もし適切なものをお探しなら セラミック材料 お客様のプロジェクトにご興味をお持ちでしたら、下記のフォームから弊社の専門家までご連絡ください。喜んでサービスを提供させていただきます。