Recently, we custom-machined a batch of Zerodur glass cavity components for a scientific research institute specializing in precision inertial navigation systems. These cavities are used in the core assembly of laser gyroscopes. Zerodur is widely recognized as a key material in high-stability optical systems due to its ultra-low coefficient of thermal expansion and outstanding optical stability.

Machining Challenges

This project involved several critical technical difficulties:

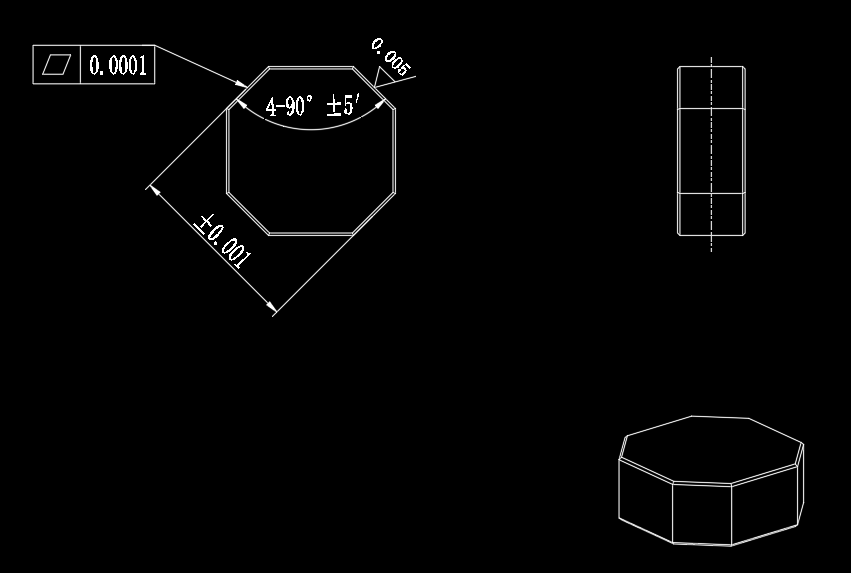

Squareness / Parallelism (≤ 0.1 μm)

- The cavity required squareness and positional tolerances within 0.1 μm, demanding exceptional geometric precision and advanced metrology support.

Angular Tolerance ±5″ (arcseconds)

- A strict angular tolerance of ±5 arcseconds (~0.0014°) was specified, which exceeds typical high-precision machining standards.

Surface Roughness Ra ≤ 5 nm

- The optical surfaces needed to achieve a surface finish of 5 nanometers Ra — falling into the optical or even sub-optical category.

Dimensional Tolerance ±0.001 mm

- The external dimensions required ultra-tight tolerances, with deviations no greater than ±1 micron.

Material-Specific Challenges

- Zerodur is a hard, brittle glass-ceramic that poses significant machining challenges. Traditional processes can easily cause microcracks, chipping, or surface defects. Special diamond tooling and customized processes were required to achieve the desired results.

Our Solution

To meet these extreme precision requirements, we implemented the following advanced processes:

Utilized 5-axis ultra-precision machining centers with diamond grinding tools to complete the complex structure in a single setup.

Operated in a temperature-controlled environment, with real-time thermal compensation and fixture stability optimization to reduce stress-induced deformation.

Applied non-contact white light interferometry for roughness evaluation and laser confocal measurement systems for in-process flatness control.

For flatness and surface quality, we employed a multi-step ultra-precision grinding and polishing workflow, with inspection and corrective compensation at each stage.

Key Technical Highlights Summary

| Specification | Achieved Result |

| Material | Zerodur glass-ceramic |

| Dimensional Tolerance | ±0.001 mm |

| Squareness / Parallelism | ≤ 0.1 μm |

| Angular Tolerance | ±5″ (≈0.0014°) |

| Surface Roughness | Ra ≤ 5 nm |

| Optical Surface Flatness | < 0.1 μm |

| Inspection & Traceability | Full process traceability + 3rd party report |

| Application | Laser Gyroscope / Inertial Navigation Systems |

Project Results

We successfully met the client’s performance targets:

Dimensional tolerance of all critical structural surfaces maintained within ±0.001 mm.

Flatness of the primary optical surfaces achieved < 0.1 μm, with surface roughness Ra reaching 5 nm.

The entire machining process is traceable, and third-party inspection reports were provided.

The client was very satisfied with the results, and the design has now moved into batch production for their experimental prototypes.

Hard and brittle material manufacturers

If you’re looking for a reliable partner with deep expertise in Zerodur ultra-precision machining, we’re here to help. Our capabilities include 5-axis simultaneous machining, sub-micron structure fabrication, and optical-grade polishing — supporting high-end applications in research, semiconductors, and photonic systems.