As an ultra-low expansion glass, Zerodur is highly recognized by high-end manufacturing for its extremely low CTE coefficient and excellent dimensional stability, while lightweight Zerodur is used in advanced optical and aerospace systems, generally using hollow or honeycomb structure design, which can reduce weight by up to 70% without excessively sacrificing mechanical properties and optical precision. Lightweighting helps reduce energy consumption while improving the performance of equipment (for example, short response speed, reduced inertia, improved observation accuracy, etc.).

Typical Applications

- Secondary and tertiary mirrors for ground-based and airborne telescopes

- VLT-M3 (Very Large Telescope, tertiary mirror)

- Satellite mirrors, optical platforms and structural supports

- Stable and lightweight components for semiconductor exposure systems

- Lightweight honeycomb satellite mirror supports

- Mirror blanks from tiny prisms to meter-sized

- Ring laser gyro (RLG) cavities

- Optical mounts for high-energy laser systems

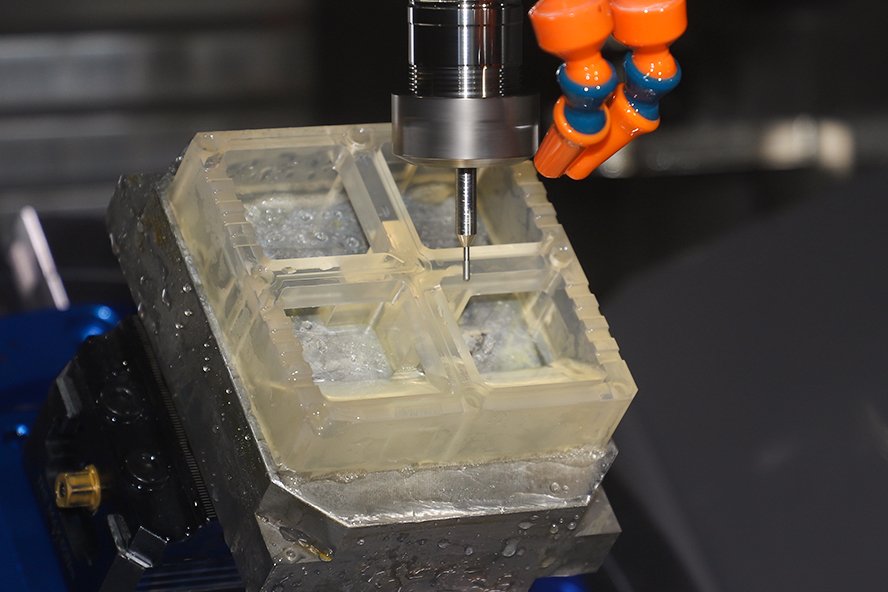

Lightweight Zerodur Machining

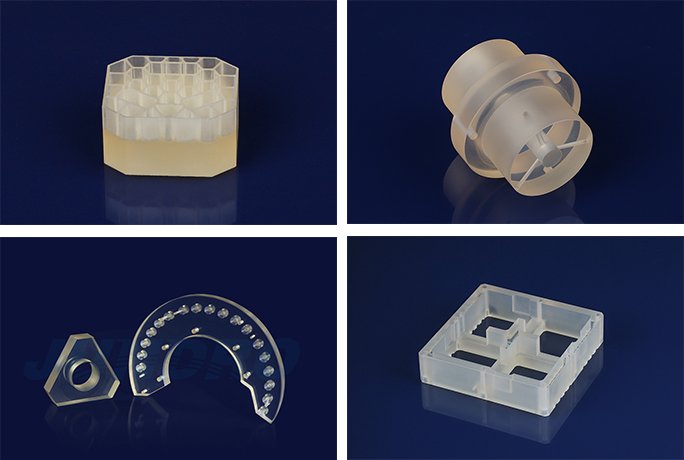

Traditional processing methods are mainly based on CNC machine tools, grinding and other processes. By using appropriate tools and parameters, excess materials can be removed to form complex structures such as grooves, thin walls, honeycombs, etc., to achieve lightweight design of parts. After machining, there will be microcracks, processing stress layers or scratches on the surface of Zerodur. At this time, acid etching can effectively remove this damaged layer so that it does not affect the optical properties and mechanical stability, and improve the surface quality. The manufacture of lightweight components usually requires advanced processing technology. Jundro has rich experience in processing Lightweight Zerodur components, which can achieve:

- Complex shapes, curved surfaces, special-shaped structures

- Processing accuracy 0.001mm

- Surface flatness up to λ/20

- Roughness below Ra 0.01 μm