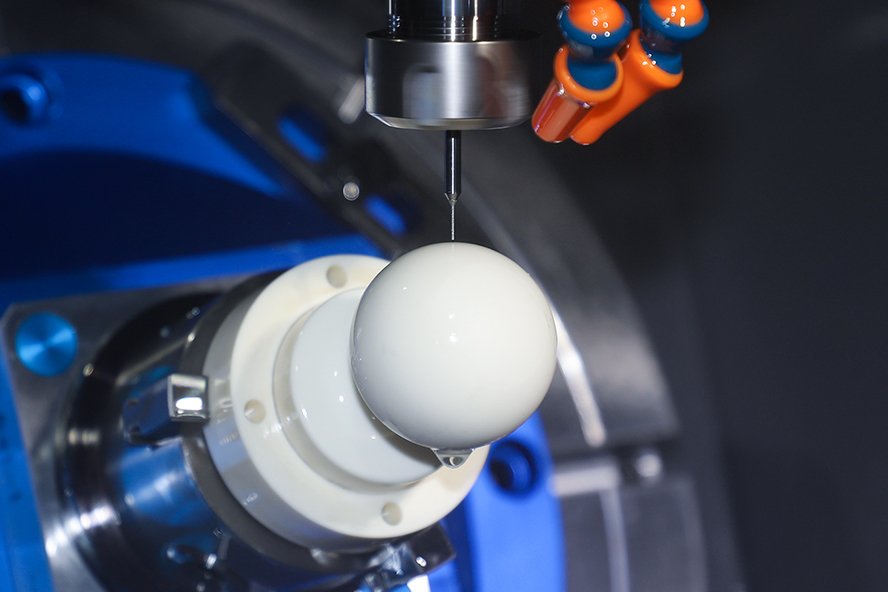

Ceramic CNC Machining & Services

Tight tolerance advanced ceramic grinding and polishing services

Through our years of experience and advanced equipment, we can perfectly achieve strict tolerances, support the machining of 18 materials, and provide a variety of advanced ceramic services, including (CNC milling and grinding, grinding and polishing, metallization, surface coating, laser engraving, etc.)

Machining Tolerances

✅ Irregular Structural Parts: Machining accuracy of 0.01mm

✅ Pipes and Rods: Cylindricity of 0.001mm, dimensional accuracy of 0.001mm

✅ Flat Surfaces: Structural part flatness accuracy up to 0.001mm, optical products with flatness accuracy of up to 1/20λ

✅ NMicrohole Structures: Minimum diameter of 0.1mm, accuracy of 0.01mm

✅ Roughness: Structural parts with Ra0.01um, optical products with Ra0.002um

Machining Materials

✅ Oxides: Aluminum oxide, zirconium oxide

✅ Nitrides: Aluminum nitride, silicon nitride

✅ Carbides: Silicon carbide, tungsten carbide, boron carbide

✅ Glass Ceramics: Macor, Zerodur, fused silica, ULE, sapphire glass, Bf33

✅ Composite materials: Shapal hi-m, silicon aluminum alloy, aluminum silicon carbide

Trusted Advanced Ceramics Manufacturer

Jundro Ceramics has been committed to challenging the rigorous and complex advanced ceramic machining projects. We have accumulated a wealth of experience and can quickly complete the machining of prototype parts. We have worked closely with the world’s top companies and research institutes. We are your preferred high-quality manufacturer for advanced ceramic material machining.

Contact us via form

Not sure which ceramic material is suitable for your application? Contact our experts for assistance