Borofloat® 33 Borosilicate Glass

Borofloat® 33 Borosilicate Glass developed by SCHOTT is a high-performance material commonly used in high-precision optics, semiconductors and high-temperature applications. It has ultra-high chemical inertness, CTE coefficient, and ultra-low refractive index, solving problems in optics, vacuum and other fields.

Borofloat® 33 Chemical Composition

| Property | Value / Description |

| Chemical Composition | SiO₂ (81%), B₂O₃ (13%), Na₂O/K₂O (4%), Al₂O₃ (2%) |

| Density | 2.22 g/cm³ |

| Mohs Hardness | 6.5 |

| Light Transmittance | 92% (Wavelength range: 350 nm – 2000 nm) |

| Maximum Operating Temperature | 450°C (up to 600°C for short-term exposure) |

Coefficient of Thermal Expansion (CTE)

Borofloat® 33 has an extremely low CTE, only 1/3 of that of ordinary glass, close to the thermal expansion rate of metal aluminum. If the project requires a lower CTE, it is recommended to choose ULE Glass or Zerodur, both of which have a thermal expansion coefficient close to 0

- 20°C–300°C:3.25 × 10⁻⁶/K

- 20°C–500°C:3.75 × 10⁻⁶/K

Refractive index (different wavelengths)

| Wavelength (nm) | 587.6 (d-line) | 656.3 (C-line) | 486.1 (F-line) |

| Refractive Index | 1.4734 | 1.4696 | 1.482 |

Melting point and thermal stability

- Softening point: 820°C

- Annealing point: 560°C

- Heat shock resistance: ΔT up to 160K (1mm thickness)

Borofloat® 33 Applications

Borofloat® 33’s low refractive index temperature coefficient (dn/dT=1.6×10⁻⁶/K) ensures that the laser system maintains beam collimation in an environment of -40°C to 200°C, solving the problem of thermally induced optical distortion of high-power lasers. In semiconductor and vacuum applications, Borofloat® 33 resists HF acid vapor corrosion in the etching process through zero porosity and ultra-high chemical inertness, extending its life by 5 times that of ordinary glass and reducing the risk of wafer contamination.

🔹Optical devices

🔹Laser windows

🔹Optical filters

🔹Wafer carriers

🔹Vacuum chamber observation windows

🔹Plasma equipment shielding plates

🔹MEMS pressure sensor substrates

🔹High temperature test equipment

Borofloat® 33 Borosilicate Glass Manufacturer

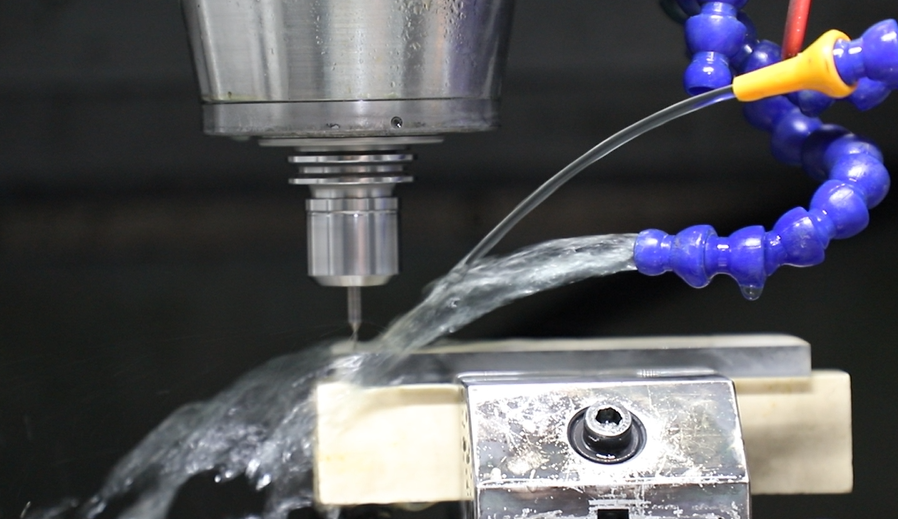

We are a high-quality manufacturer of ceramic and glass materials, specializing in machining difficult materials. We use our professional technology and advanced equipment to provide customers with excellent services. For optical glass materials, we provide irregular, round, curved surface processing, etc., with processing accuracy up to 0.001 and plane accuracy up to 1/20λ

If you need to choose Borofloat® 33 glass for your project, please contact our experts and we will provide strong support for your project.

FAQ

What is the flatness standard of Borofloat 33? How does it affect the optics?

Flatness requirements: The standard flatness of Borofloat 33 is ≤5μm/m (in accordance with ISO 10110 optical glass standard), and can reach ≤1μm/m after high-precision processing.

- Laser system: Uneven surface will cause beam scattering and reduce energy transmission efficiency.

- Semiconductor lithography: Uneven substrate will cause exposure pattern distortion, which needs to be controlled at ≤0.5μm/m.

- Solution: Select float process original film and reduce internal stress deformation through precision annealing process.

What is the softening temperature of Borofloat 33?

Softening point: 820°C (normal use temperature upper limit 450°C, short-term tolerance 600°C).

High temperature application restrictions:

Long-term use: Exceeding 450°C will accelerate crystallization, and it is recommended to use an anti-crystallization coating (such as silicon nitride).

Thermal shock risk: The temperature difference during rapid cooling must be ≤160K (thickness 1mm) to avoid cracking.

Typical applications: High-temperature observation windows (such as furnace sight glasses) need to be designed with a gradual temperature structure to prevent edge stress concentration.

Borofloat 33 vs. other glass materials for thermal expansion coefficient (CTE)

| Material | CTE (20°C–300°C, ×10⁻⁶/K) | Comparison of applicable scenarios |

| Borofloat 33 | 3.25 | Precision Optics/Semiconductors (CTE Matching Metals) |

| Ordinary soda lime glass | 8.5–9.0 | Building/Packaging (low-cost and low-demand scenarios) |

| Quartz glass | 0.55 | Extremely high temperature (but high cost and difficult to process) |

Does the optical performance of Borofloat 33 support applications from UV to IR?

Transmittance range:

Ultraviolet (UV): transmittance > 80% (from 350nm).

Visible light: 92% (550nm wavelength).

Infrared (IR): > 90% (to 2000nm), reduced to 50% at 2500nm.

Application adaptability:

Recommended scenarios: laser (1064nm), infrared sensor window, UV disinfection lampshade.

Restricted scenarios: For far infrared (> 3μm) applications, it is recommended to use calcium fluoride (CaF₂) or zinc selenide (ZnSe) instead.