Characteristics and Engineering Applications of Aluminum Nitride

Aluminum nitride (AlN) is an advanced ceramic material with excellent performance, widely used in high-end engineering fields due to its extremely high thermal conductivity, excellent electrical insulation, low thermal expansion coefficient, outstanding high temperature resistance, and excellent chemical stability. Unlike aluminum nitrate, aluminum nitride is a compound of nitrogen with an oxidation state of -3 in its chemical formula, while aluminum nitrate is a salt or ester form of nitrate. Aluminum nitride has a hexagonal wurtzite crystal structure, which endows it with unique physical and chemical properties.

Aluminum Nitride Engineering Applications

1.High-Power Electronic Packaging and Substrates

Application Scenarios: IGBT modules, RF power devices, and high-frequency microwave components.

Why Aluminum Nitride is Used

- High Thermal Conductivity: Efficiently dissipates heat to protect electronic components.

- Thermal Expansion Matching: Matches silicon chips to reduce mechanical stress.

- Excellent Insulation: Ensures electrical reliability under high power conditions.

Engineering Applications

- Power Semiconductor Device Substrates

- High-Frequency Packaging for 5G Communication

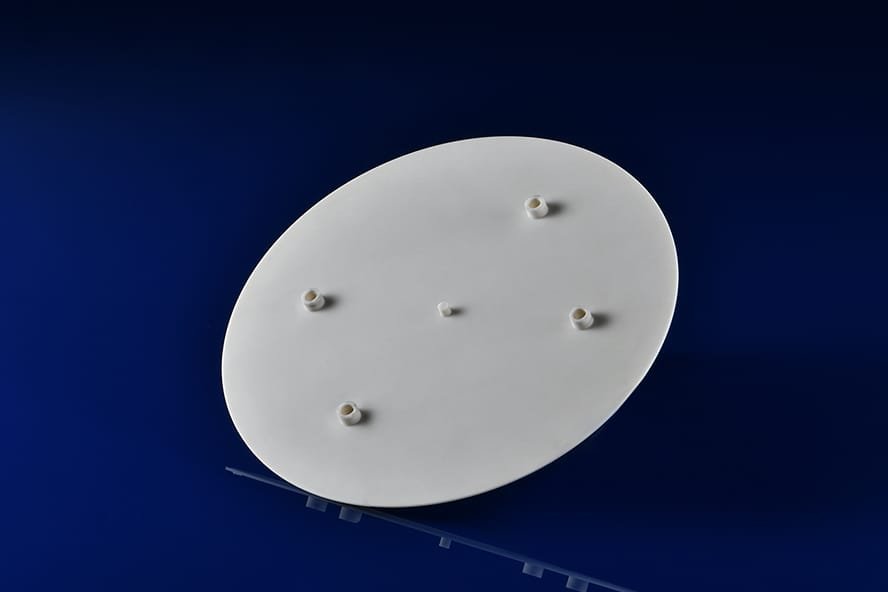

2.Semiconductor Manufacturing Components

Application Scenarios: Wafer support parts and high-temperature sintering platforms in semiconductor manufacturing

Why Aluminum Nitride is Used:

- High-Temperature Stability: Withstands high-temperature processes without oxidation.

- Thermal Expansion Matching: Minimizes thermal damage to silicon wafers.

Engineering Applications

- Wafer Carriers and Base Materials in Semiconductor Processing

- High-Temperature Fixtures and Support Structures

3.Microwave Devices and RF Systems

Application Scenarios: Insulating substrates and thermal management for microwave and RF components.

Why Aluminum Nitride is Used:

- Low Dielectric Constant and High Insulation: Ensures stable high-frequency signal transmission

- High Thermal Conductivity: Maintains reliability of RF systems by dissipating heat effectively.

Engineering Applications

- Microwave Substrates for 5G Communication Modules

- RF Amplifier Packaging Substrates

4.Laser and Optical Device Packaging

Application Scenarios: Heat management and structural packaging for high-power lasers and optical components

Why Aluminum Nitride is Used:

- Superior Thermal Management: Maintains stable laser operation by effective heat removal.

- Electrical Insulation and Mechanical Stability: Ensures high reliability under high-voltage and high-temperature conditions.

Engineering Applications

- Heat Dissipation Components for High-Power Lasers

- Structural Parts for Optical Devices

5.Thermal Management in Aerospace Systems

Application Scenarios: Thermal control components for satellite electronics and high-temperature structural parts.

Why Aluminum Nitride is Used:

- High Thermal Conductivity and Lightweight Structure: Essential for heat dissipation and weight reduction.

- High Temperature and Corrosion Resistance: Suitable for vacuum and extreme thermal cycles.

Engineering Applications

- Thermal Substrates in Satellite Power Systems

- High-Temperature Bases for Aerospace Sensors and Controllers

Potential of aluminum nitride in future engineering applications

With the rapid development of science and technology, the demand for aluminum nitride in cutting-edge fields such as new energy vehicles, 5G communications, and high-power electronic devices will continue to rise.

Material innovation: Aluminum nitride-based composite materials are expected to further improve mechanical properties and thermal management effects.

Cost optimization: As the production process matures, the cost of aluminum nitride is expected to decrease, promoting its large-scale application.

Summary of Aluminum Nitride Engineering Applications

Summary of aluminum nitride engineering applications

Aluminum nitride plays a key role in semiconductor packaging, optical equipment, aerospace, and power electronics due to its advantages such as high thermal conductivity, electrical insulation, high strength, and thermal expansion coefficient matching with silicon. Choosing aluminum nitride as a core material can solve engineering problems such as heat dissipation, electrical insulation, and thermal stress management. It is one of the irreplaceable materials in high-end engineering applications.

If you are looking for the right ceramic material for your project, please contact our experts through the form below. We will be happy to provide you with service