Do you still think that heat dissipation in modern electronics is simply about keeping components cool? Why are traditional metal heat sinks gradually being replaced by aluminum nitride (AlN) heat sinks? Thermal management—a critical factor concerning performance, reliability, and product lifespan—is why it’s a top priority for engineers.

Why AlN Heatsinks Matter

In the past, traditional metal heat sinks were widely used for their excellent thermal conductivity. However, as application scenarios evolved, electrical insulation became equally essential. Engineers required good electrical insulation, which often meant adding an intermediate layer that increased thermal resistance.

The emergence of aluminum nitride (AlN) has filled this gap. With a high thermal conductivity of 170–230 W/m·K and an intrinsic dielectric strength exceeding 10 kV/mm, AlN can come into direct contact with high-voltage components without compromising heat dissipation efficiency. Moreover, its low coefficient of thermal expansion, similar to that of silicon, minimizes stress during thermal cycling—addressing the major risks of traditional ceramic materials and metal heat sinks, such as warping and microcracks.

The Material Behind the Advantage

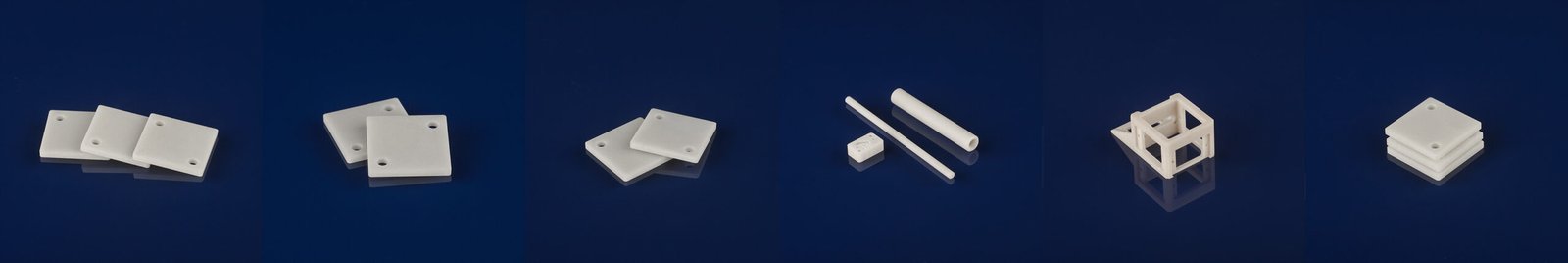

Unlike most materials, aluminum nitride can be precisely machined into complex geometries, enabling custom heat sink designs optimized for airflow, surface area, and component layout. This level of precision is critical in aerospace, semiconductor, and medical device applications, where even a millimeter of deviation can affect thermal performance.

High Thermal Conductivity with Electrical Isolation

Unlike alumina, which tops out at ~25 W/m·K, AlN conducts heat nearly 10× faster while maintaining full insulation. This makes it ideal for semiconductor, aerospace, and optoelectronic assemblies.

Dimensional Precision for Custom Thermal Designs

Advanced CNC machining of AlN ceramics allows engineers to design heatsinks with tight tolerances (±0.01 mm), integrated channels, or optical-grade surfaces—something rarely achievable with traditional ceramics.

Thermal Expansion Compatibility

With a CTE close to silicon, AlN minimizes thermal stress during power cycling—critical for long-term stability in semiconductor or power electronic systems.

Cleanroom-Grade Reliability

AlN is chemically stable, non-toxic, and resistant to plasma corrosion, making it a trusted choice for semiconductor processing, vacuum systems, and laser modules.

Custom AlN Heatsink company

The performance of aluminum nitride heat sinks depends on their manufacturing process. Partnering with Jundro Ceramics ensures that each heat sink possesses the following characteristics.

- Uniform density and microstructure

- Flatness within microns

- Surface roughness down to Ra0.01 µm

- Consistent thermal performance across batches

Such precision translates directly into real-world reliability—lower device temperatures, higher operational stability, and reduced field failures.

By working closely with Jundro ceramics specialists, procurement teams can ensure each component is optimized for both function and manufacturability, reducing risk and total system cost.