Al₂O₃ Ceramics Machining Services

Precision CNC Machining for 95%, 99%,99.5%,and 99.8% Al₂O₃ Components with Tight Tolerances and Fast Turnaround

Materials We Support

We specialize in machining various grades of alumina ceramics, including:

95% Alumina – cost-effective, general-purpose

99% Alumina – high-purity for mechanical and thermal applications

99.5% Alumina – ideal for demanding vacuum and electronic insulation environments

99.8% Ultra-Pure Alumina – available upon request for semiconductor and medical use

Our experience covers a wide range of part sizes, shapes, and material hardness.

Machining Capabilities

With our advanced equipment and rich experience in machining, we can achieve:

- Processing accuracy as low as 0.001mm

- Flatness accuracy up to 0.002mm

- Surface roughness (Ra) as low as Ra0.02um

- Micro-hole drilling as small as 0.16mm diameter

- Custom-shaped parts, slots, grooves, and thin walls

- No-crack edge finishing and complex contours

We handle everything from rapid prototyping to small- and medium-volume production runs.

Application & Case Studies

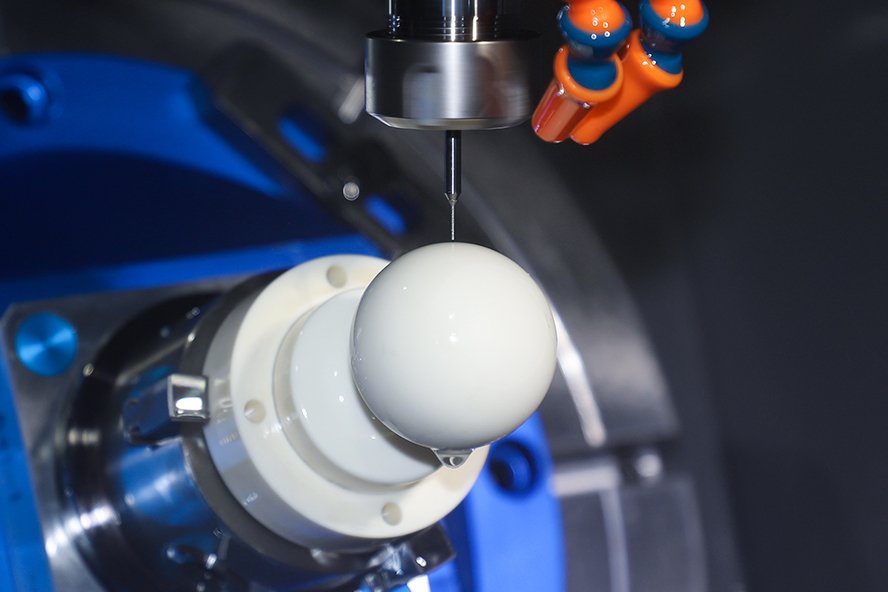

Complex Shape Alumina Machining Process

Get a Quote Today

👉 Click to Contact Our Engineers or fill out the form below for a quick response

Frequently Asked Questions

We perform:

3D CMM inspection

Surface roughness measurement

Optical flatness testing

Material purity verification

ISO 9001 & ISO 14001 quality control

Small batches: 7–12 days

Complex / large parts: 15–20 days

Urgent orders can be expedited.

Absolutely. Simply provide 2D/3D drawings (STEP, STP, PDF) and your tolerance, surface, and application requirements.

Yes. We offer engineering support to improve structural strength, reduce breakage risk, and lower machining cost.

Yes. Services include:

Fine grinding

Ra0.02 μm polishing

Optical mirror finish

Laser engraving