Bending strength generally refers to the ability of a material to resist fracture under bending loads. Although both materials possess excellent properties, their bending performance differs due to variations in purity and sintering processes. Today, we will test aluminum nitride ceramics and alumina ceramics using a tensile testing machine, based on a commonly used 40 mm span and approximately 4 mm × 3 mm cross-sectional dimensions, to determine the force each can withstand before breaking. This value is the bending strength.

Flexural strength of aluminum nitride

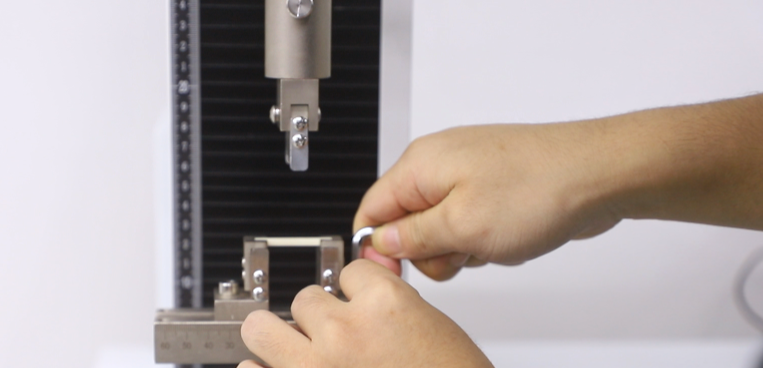

Both materials were tested using the same loading speed, loading point spacing, and testing environment to ensure that each specimen was tested under completely consistent conditions. First, we mounted the aluminum nitride ceramic onto the tensile testing machine to begin the test.

When clamping, ensure that the force is even and avoid eccentricity.As can be seen in the test, the force applied to the aluminum nitride kept increasing, and the aluminum nitride ceramic fractured at 348N.

| project | AlN |

| Width (mm) | 4 |

| Thickness (mm) | 3 |

| Bottom Span (mm) | 36 |

| Maximum Force (N) | 348 |

| Maximum Bending Strength (MPa) | 522 |

Flexural strength of Alumina

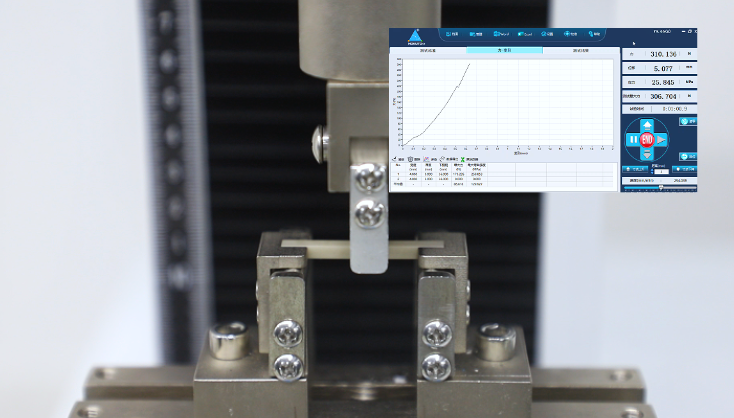

The alumina ceramic was also clamped, and then the testing began.

We can see that under the same three-point bending test conditions, aluminum nitride can withstand higher loads and exhibits higher bending strength; aluminum oxide is relatively lower, but it is within the normal range of material properties.

| project | Alumina |

| Width (mm) | 4 |

| Thickness (mm) | 3 |

| Bottom Span (mm) | 36 |

| Maximum Force (N) | 253 |

| Maximum Bending Strength (MPa) | 380 |

Conclusion

Although aluminum nitride has better bending resistance than aluminum oxide, design decisions should still consider thermomechanical properties, dielectric properties, cost, and manufacturability, not just bending strength.