To obtain defect-free fused silica precision parts, it is necessary to master appropriate processing methods and equipment. As the preferred material for aerospace, semiconductors, and optics, quartz possesses an ultra-low coefficient of thermal expansion, excellent optical transparency, and good chemical resistance. The following points will help you understand how to precision machine quartz glass parts.

Challenges in Machining Fused Silica Glass

- Chipping and Cracking: Conventional cutting tools can induce stress, causing chips or fractures.

- Surface Roughness: Achieving optical-grade finishes requires sub-micron precision.

- Tool Wear: The hardness of fused silica leads to rapid tool abrasion, increasing production costs.

- Dimensional Accuracy: Maintaining tight tolerances, especially for microstructures, is difficult without advanced CNC and diamond tooling.

Best Practices for Fused Silica Glass Machining

To maximize efficiency and quality, We typically employ the following strategies:

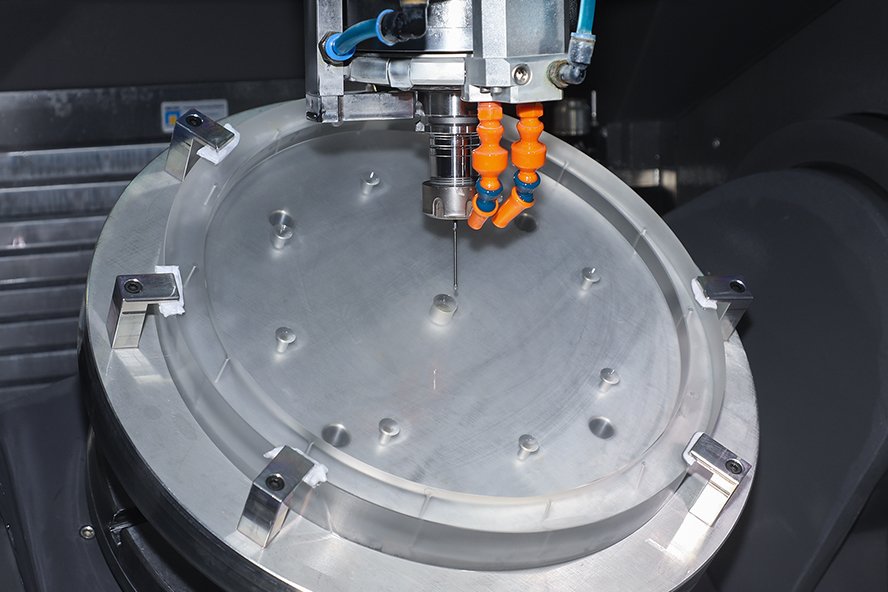

Use Diamond Tools: Prioritize diamond-coated or monocrystalline diamond tools for all cutting and grinding operations.

Control Cutting Parameters: Low feed rates and optimized spindle speeds reduce thermal and mechanical stress.

Cooling and Lubrication: Employ deionized water or specialized coolants to minimize heat accumulation and prevent micro-cracks.

Quality Inspection: Use interferometry, surface profilometry, and microscopy to verify surface roughness and dimensional accuracy.

Custom Fixturing: Secure parts with precision jigs to reduce vibration and stress during machining.

Applications of Fused Silica

High-precision fused silica machining is critical in industries that demand performance under extreme conditions:

Semiconductors: Fabrication of photomask blanks, substrates, and high-temperature furnace components.

Optics: Lenses, prisms, mirrors, and optical windows for lasers and telescopes.

Aerospace and Defense: Structural components for satellites, high-temperature sensor housings, and aerospace instrumentation.

Medical Devices: Transparent enclosures, diagnostic equipment, and microfluidic devices requiring biocompatibility and chemical resistance.

Chinese manufacturer of Fused Silica Machining

As a leading Chinese manufacturer of fused silica machining, Jundro specializes in precision shaping, grinding, and polishing of high-purity fused silica components. Leveraging advanced 5-axis CNC machines, diamond tooling, we deliver custom optical, semiconductor, and aerospace parts with exceptional surface quality and dimensional accuracy. With years of experience, strict quality control, and ISO-certified production standards, we provide reliable, high-precision fused silica solutions tailored to meet the most demanding industrial applications.