In modern plasma and ion source technology, reliability depends on materials that can endure extreme electric fields, thermal cycling, and high-vacuum environments. Among all engineering ceramics, alumina (Al₂O₃) remains the preferred choice for RF and DC plasma applications — balancing mechanical strength, electrical insulation, and chemical stability.

Why Alumina is Ideal for Ion and Plasma Sources

Alumina ceramics combine several critical advantages that make them indispensable for plasma-based systems:

Excellent dielectric strength for high-voltage and RF applications

High thermal stability, maintaining structure and insulation up to 1600 °C

Vacuum compatibility — extremely low outgassing and contamination

Resistance to plasma erosion and reactive gases such as Ar, O₂, or CF₄

Precision machinability for complex geometries and fine tolerances

These properties make alumina ideal for both RF plasma sources operating at 13.56 MHz and ion beam systems where precise electrical isolation and vacuum sealing are essential.

Common Alumina Components Used in Ion and Plasma Sources

Cup-shaped discharge chambers

Used as plasma confinement cavities.

Provide electrical isolation between cathode, anode, and extraction electrodes.

RF vacuum windows

Transmit 13.56 MHz RF power into the plasma chamber.

Designed to withstand vacuum pressure and temperature cycling.

Insulating rings and spacers

Separate metal electrodes and structural parts.

Maintain mechanical alignment under high-voltage operation.

Gas feedthrough insulators and support tubes

Used to introduce gases or cooling lines while maintaining vacuum integrity.

Custom-machined alumina components for research laboratories and OEM manufacturers involved in plasma systems, ion sources, and related high-vacuum equipment.

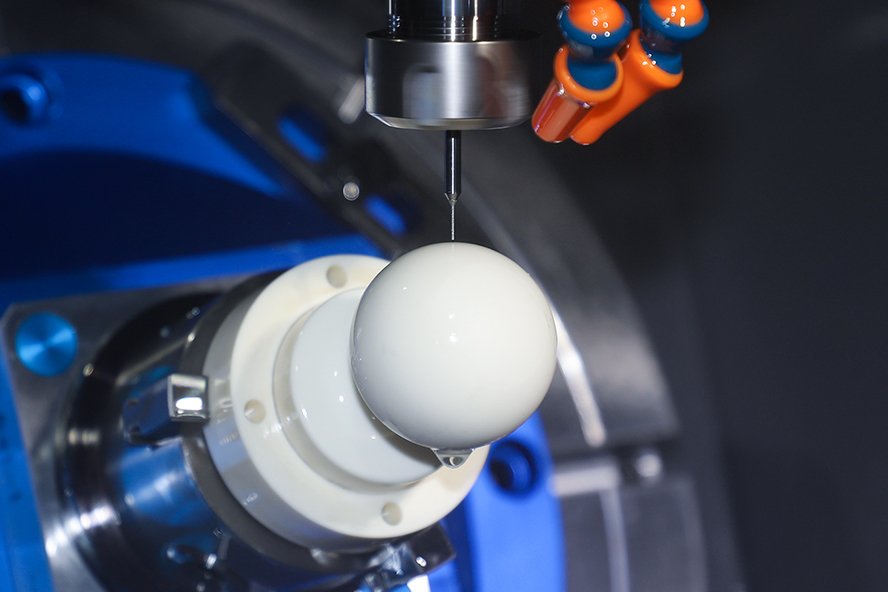

Precision Machining Capabilities

At Jundro Ceramics , we have advanced 3-axis, 4-axis, and 5-axis CNC machining centers capable of achieving:

Dimensional tolerance: ±0.01 mm

Surface roughness: Ra 0.01 μm

Flatness: up to 0.001 mm

Complex internal and external geometries

Each part is manufactured under strict ISO 9001 quality control and can be customized according to drawings or 3D CAD files (STEP, STP, PDF).

Applications We Support

RF plasma generators and etching systems

Ion and neutral beam sources

Accelerator and fusion research

Semiconductor deposition and sputtering systems

Space propulsion and plasma diagnostics

We have successfully supplied alumina parts, including cup-type ion source chambers, to international research institutes and plasma equipment manufacturers.