The first step in ceramic manufacturing is to determine the specific requirements, including the material to be used, quantity (the larger the quantity, the lower the cost), and drawing details such as tolerance requirements (tighter tolerances increase costs), chamfer size, surface roughness, hole diameter, and depth.

These parameters are crucial for the technical team to accurately calculate pricing.

If cost is a concern, the best approach is to keep the design simple, use general tolerances, and choose a relatively low-cost material (alumina is the most economical among ceramic materials).

Material Selection

Material selection should be based on the application requirements:

Cost-sensitive projects: Alumina (Al₂O₃)

Wear resistance and long service life: Zirconia (ZrO₂)

Excellent electrical insulation: Macor machinable glass ceramic

Thermal management applications: Aluminum Nitride (AlN)

Ultra-low thermal expansion: Zerodur glass ceramic (relatively expensive)

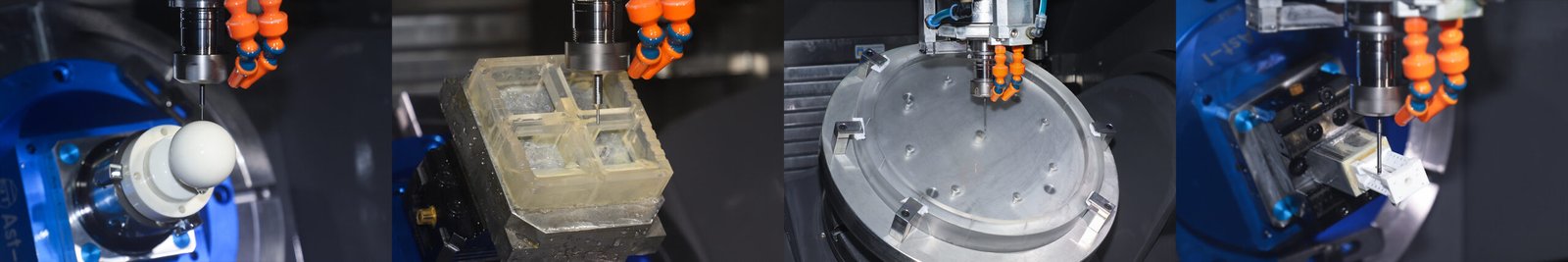

CNC Milling Machining

Using 3-, 4-, and 5-axis CNC machines, we can achieve complex geometries from your drawings, including drilling (micro-holes, angled holes) and threading (most ceramic materials support threads as small as M1.2, though they are not always practical).

Except for Macor and Shapal-HM, all other materials require custom diamond tools for machining.

This material is ideal for prototyping and small-batch production. However, the toughness of the machined parts is generally lower than that of sintered ceramics

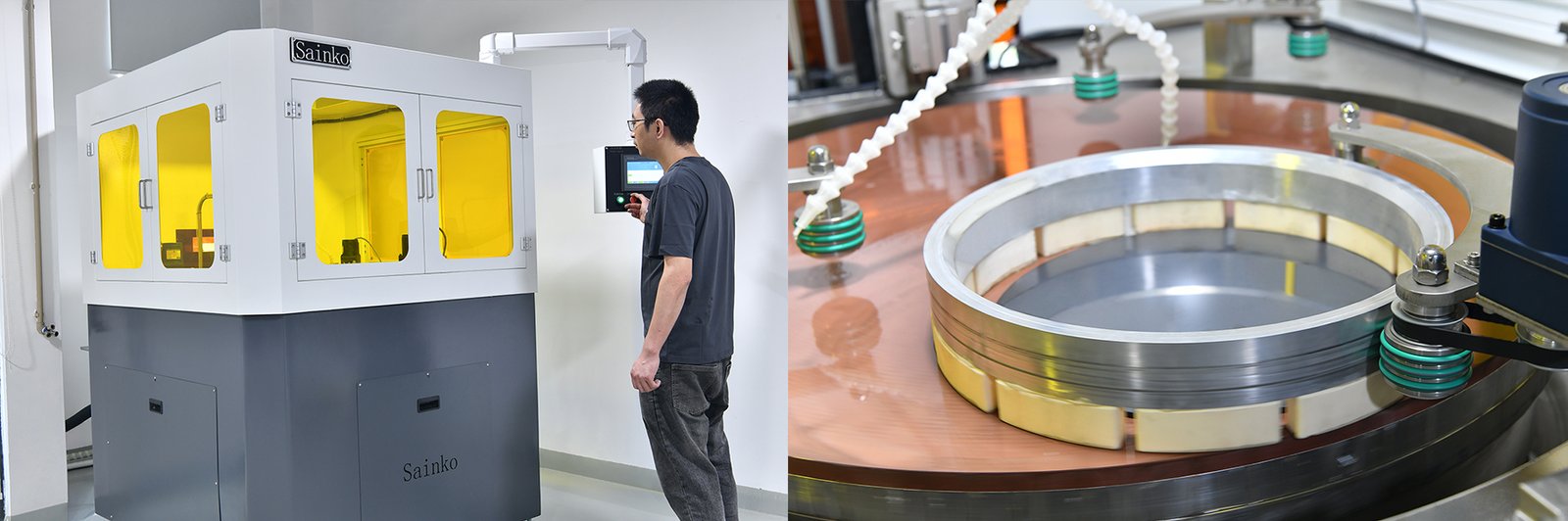

Double-Sided Grinding

By selecting a suitable grinding wheel (grit size 80 to 2000), double-sided grinding allows for simultaneous control of surface roughness and parallelism of parts, helping to reduce internal stress and improve part uniformity.

Depending on the application requirements, this step is typically followed by polishing or coating.

Polishing

According to the drawing requirements, polishing achieves a mirror-like surface finish and high smoothness.

Materials such as zirconia and silicon carbide can reach extremely fine surface roughness, as seen in SiC mirror applications.

Inspection and Quality Control

Each part undergoes dimensional inspection using CMM (Coordinate Measuring Machines) and other precision testing equipment to ensure consistency with drawing specifications.

Cleaning and Packaging

After machining, parts are cleaned using ultrasonic cleaning machines to remove residues such as cutting fluids, grinding compounds, and polishing agents.

They are then oven-dried, sealed in anti-static vacuum bags, and packed in appropriately sized boxes with foam or pearl cotton cushioning to prevent pressure damage during shipping.

Finally, both inner and outer labels are attached for easy identification by the customer and internal staff.

Why Choose a Professional Ceramics Manufacturer

With a complete process flow and years of experience in advanced ceramics manufacturing, we help you achieve parts that meet your functional and quality requirements — from material selection to design, inspection, and packaging, we provide comprehensive end-to-end service.