Definition of Fused Quartz

Fused Quartz / Fused Silica is an amorphous glass obtained by melting and rapidly cooling high-purity silicon dioxide. It features an extremely low coefficient of thermal expansion, excellent optical transmission (covering UV–visible–infrared ranges), high thermal resistance, and strong chemical corrosion resistance. These properties make it a key material in demanding applications such as semiconductor equipment components, aerospace sensors, and vacuum chambers.

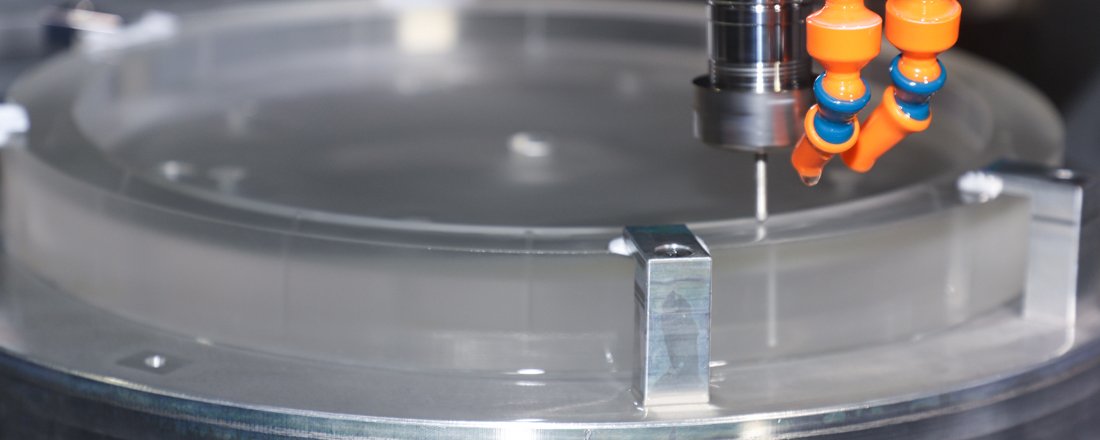

Fused Quartz Parts Machining Capabilities

Machining Equipment: Multi-axis CNC precision milling, laser cutting & marking, ultra-precision surface grinding & polishing, ultrasonic cleaning, and cleanroom packaging.

High-Precision Capabilities:

Complex shapes: tolerances up to ±0.01 mm

Cylindrical/shaft components: tolerances up to ±0.001 mm

Surface flatness: up to 0.001 mm

Optical flatness: up to 1/20λ (depending on wavelength)

Micro-holes: diameters as small as 0.1 mm (tolerance ±0.01 mm)

Surface roughness: Ra 0.01 μm for structural parts, Ra 0.002 μm for optical components

Surface Treatment: Polishing, optical coating

Inspection Equipment: Coordinate Measuring Machine (CMM), interferometer, profilometer, surface roughness tester, roundness tester, etc.

Quality System: ISO 9001 & ISO 14001, ISO 13485 certified. Inspection reports provided (FAR/FAI, measurement reports, surface quality reports).

Machining Process Flow (From Drawing to Finished Part)

Requirement Confirmation & DFx Review: Upon receiving 2D/3D drawings, material specifications, critical tolerances, batch size, and delivery schedule, a machinability assessment is conducted. Design optimization suggestions are provided (e.g., hole buffering, minimum wall thickness, support structures).

Material Preparation: Procure fused quartz plates/rods/preforms according to grade, with full batch records and certificates.

Rough Machining: Saw cutting and CNC rough milling to achieve near-net shape, leaving allowance for polishing.

Thermal Stress Annealing (if required): Relieve residual machining stress to prevent cracks during subsequent processes.

Precision Machining: Multi-axis machining, micro-holes, angled holes, and other fine features.

Ultra-Precision Grinding & Polishing: Achieve required flatness and optical-grade surface roughness.

Cleaning & Coating (if required): Ultrasonic/DI water cleaning, vacuum drying, and pre-treatment for anti-reflective or protective coatings.

Final Inspection & Packaging: Inspection reports issued according to the quality plan. Components are packed in anti-static, cleanroom packaging with batch and inspection labels.

Common Specifications & Feasibility

Minimum Feature Size: Micro-holes from 0.1 mm; smaller features possible with evaluation of sample requirements.

Dimensional Tolerances: ±0.01 mm for complex surfaces; ±0.001 mm for shafts and cylindrical parts.

Flatness / Optical Requirements: 0.001 mm flatness for structural parts; optical flatness up to 1/20λ.

Surface Roughness: Ra 0.01 μm for structural components; Ra 0.002 μm for optical components.

Maximum Machining Size: Adjustable according to material blanks and equipment capacity — drawings welcome for confirmation.