Alumina Custom Parts

As an ISO 9001 certified manufacturer specializing in custom alumina ceramic parts with a ±0.001 mm tolerance, we can deliver a significant performance improvement to your project.

Product & Capabilities

We offer ultra-precision machining for alumina ceramic parts to meet the most demanding specifications:

Standard tolerances: ±0.01 mm

Ultra-precision tolerances: ±0.001 mm for cylindrical and structural parts

Flatness: up to 0.001 mm for critical surfaces

Surface roughness: as low as Ra 0.01 μm for structural parts, and Ra 0.002 μm for optical finishes

Dimensions:

Minimum size: micro-components as small as 0.5 mm

Maximum size: up to 500 mm in length/diameter (depending on geometry)

Material Purity Options

We supply and process alumina ceramics in multiple purity grades to suit different applications:

95% Al₂O₃ – Excellent mechanical strength and wear resistance

99% Al₂O₃ – Higher hardness and electrical insulation performance

99.8% Al₂O₃ – Maximum thermal stability and chemical resistance, ideal for high-temperature and ultra-clean environments

Machining & Finishing Methods

Our advanced machining capabilities allow complex and high-precision alumina components, including:

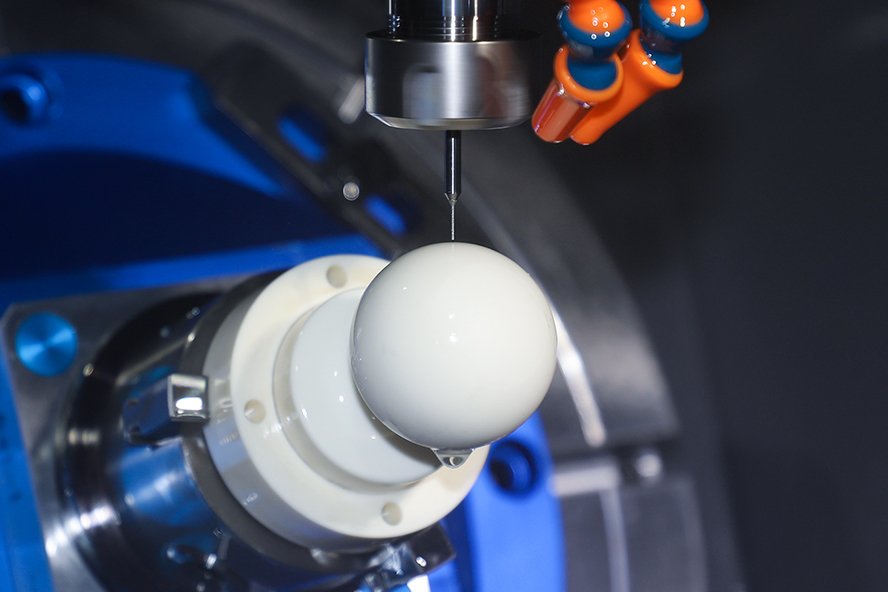

CNC Milling – 3, 4, and 5-axis precision machining

Surface Grinding – Flatness up to 0.001 mm

Polishing – Optical and mirror finishes available

Laser Cutting & Drilling – Micro-holes down to 0.1 mm diameter with ±0.16 mm accuracy

Chamfering, Slotting, and Threading – For functional integration in assemblies

Custom Shapes & Geometries

We manufacture alumina parts in a wide range of shapes, including but not limited to:

Plates & Substrates – Precision-cut flat parts for electronics and thermal management

Rods & Tubes – Cylindrical shapes for mechanical and insulating functions

Rings & Discs – Sealing, bearing, and structural components

Complex 3D Forms – Multi-axis machining for intricate geometries and prototypes

Custom Profiles – Based on customer CAD drawings or reverse-engineering from samples

Custom Shapes & Geometries

Contact us via form

Not sure which ceramic material is suitable for your application? Contact our experts for assistance