Zerodur Glass Ceramic

Close to zero coefficient of thermal expansion

Zerodur Glass Ceramic has excellent optical properties, a uniform internal structure, and strong tolerance to chemical substances. Its performance is comparable to Corning’s ule glass. It is often used in optical lenses, laser gyroscopes, and specific laser components.

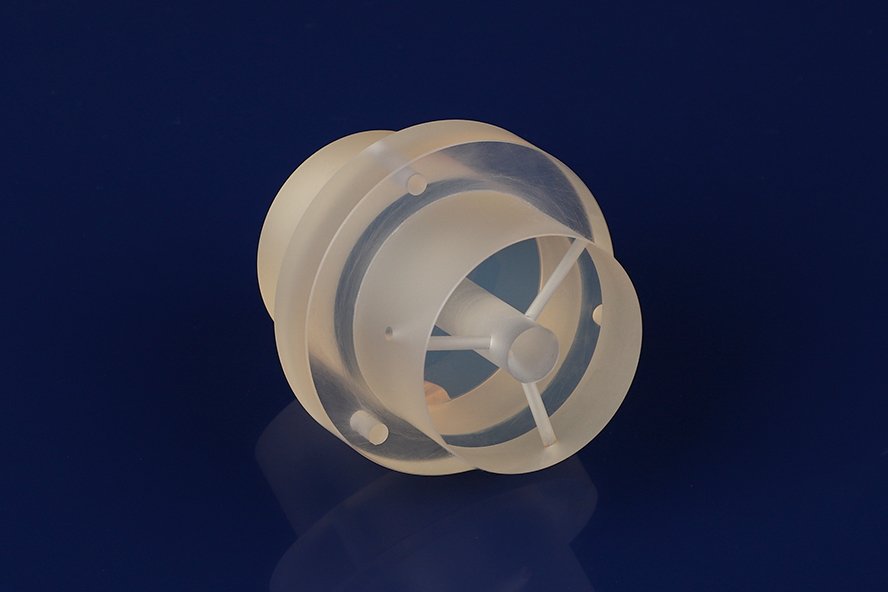

Laser gyro components

Zerodur Glass Ceramic Properties

| Material | Zerodur Glass Ceramic |

| Color | Light yellow brown |

| Density g/cm³ | 2.53 |

| Knoop hardness HK 0.1/20 | 620 |

| Refractive index nd | 1.5424 |

| Abbe number vd | 56.1 |

| Thermal conductivity at 20°C [W/(m·K)] | 1.46 |

| Average value of Young’s modulus E[GPa] at 20°C | 90.3 |

| Resistivity at 20℃ p[Ω·cm] | 2.6 × 10¹³ |

| Internal transmittance Ti at 580 nm/5 mm thickness | 0.95 |

| Coefficient of Thermal Expansion (0°C; 50°C)* | 0 ± 0.007 × 10⁻⁶ /K |

Disclaimer: This value is for reference only and may vary slightly from batch to batch.

Applications

Laser gyro mirror and bracket

As one of the core materials of ring laser gyroscopes, zerodur is mainly used to manufacture reflectors and support structures. Its thermal expansion characteristics close to zero ensure that the optical path can be kept stable when the temperature changes, thereby improving the accuracy of the navigation system

X-ray mirrors in synchrotrons

For example, the European X-ray Free Electron Laser (European XFEL) uses Zerodur mirrors to ensure stability in high-radiation environments

Interferometers, optical platforms and other measurement systems

In the field of industrial measurement, Zerodur can eliminate errors caused by temperature due to its own low CTE characteristics, and is suitable for most high-precision detection equipment

Telescope lenses and reflectors

Zerodur is the mainstream material for large telescopes. Typical cases include (Hubble Space Telescope primary mirror, Extremely Large Telescope (ELT) infrared and radio telescopes)

What we can do

- Cylindricity 0.001mm

- Minimum internal thread M1.2

- Flatness 1/20λ(Φ300)

- Concentricity 0.005mm

- Parallelism 0.001mm

- Roughness Ra0.01um

- Processing accuracy 0.001mm

- Maximum size 500*500mm

Contact us via form

Not sure which ceramic material is suitable for your application? Contact our experts for assistance