Ceramics machining may seem simple, but it’s actually quite complex. Even a tiny sharp edge, an undersized hole, or a poorly designed corner can cause parts to crack, chip, or even malfunction. This article will reveal five key principles to help you ensure the integrity, functionality, and durability of your ceramic parts, enabling them to withstand the most demanding applications.

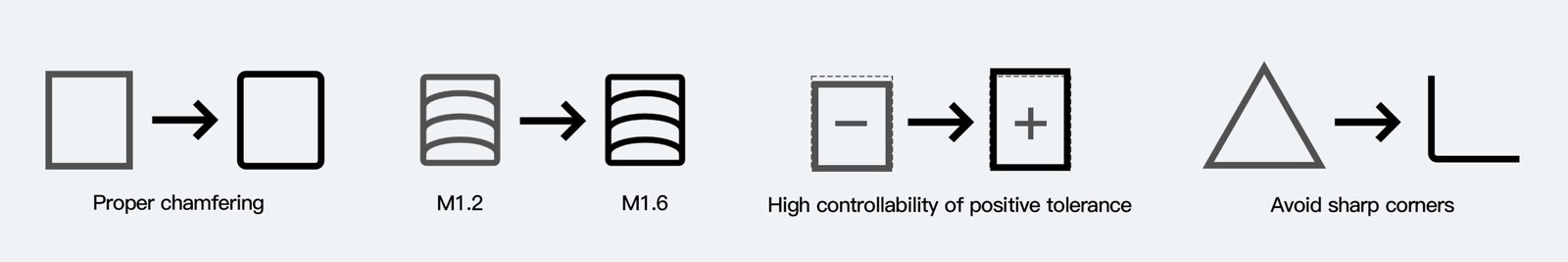

Why Chamfers Are Necessary

Ceramics, also known as hard and brittle materials, experience the highest stress concentration at edges, making chipping or micro-cracks very likely. Chamfers can:

Distribute stress more evenly

Remove sharp edges

Protect the part during handling, reducing the risk of scratches

Avoid interference during assembly

For ceramics, preventing cracks starts with properly designed chamfers.

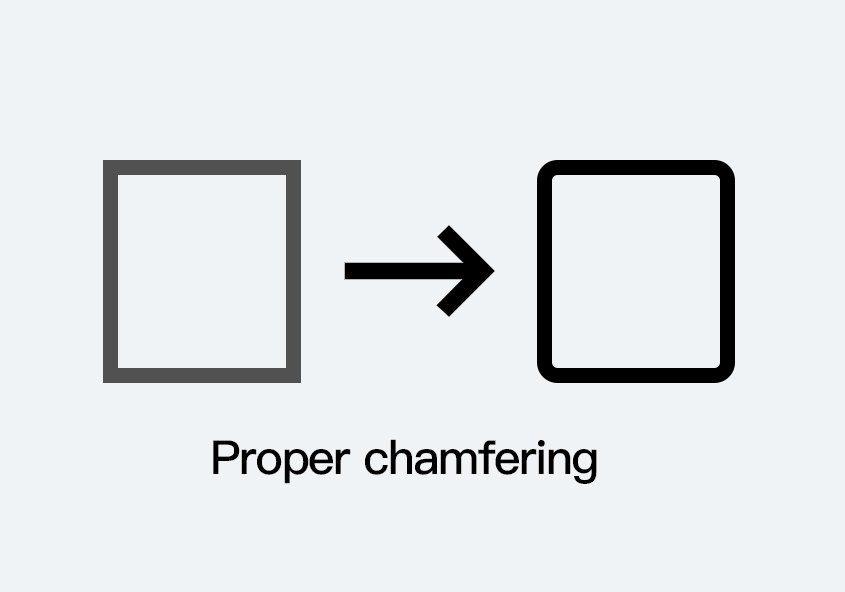

Why M1.2 Threads Are Not Recommended

Ceramics have limited tensile strength. Small threads with sharp roots concentrate stress, making stripping, chipping, or breaking very likely. Additionally, the small hole diameter makes assembly tolerances extremely difficult to control. A minimum thread size of M1.6 is recommended.

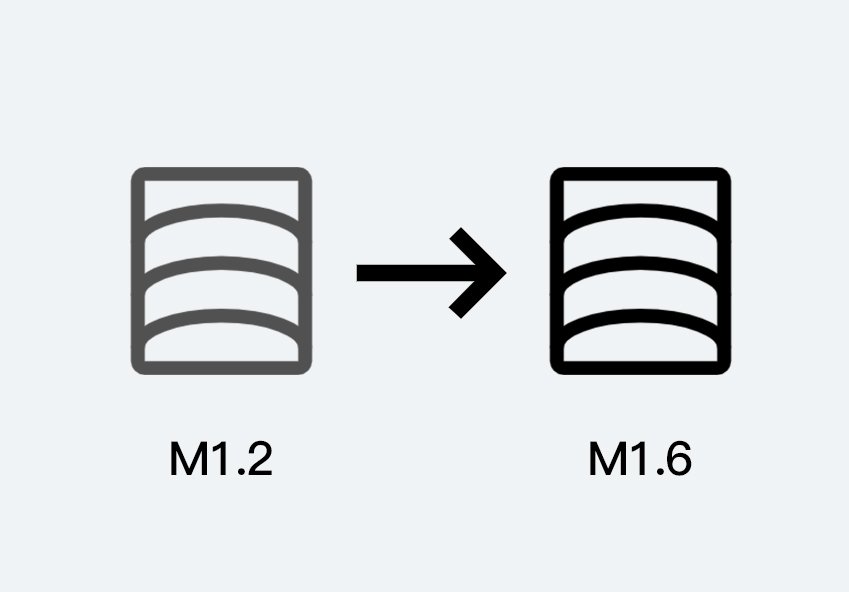

Why Negative Tolerances Are Harder to Control

Ceramics lack ductility. Once material is over-removed during machining, it cannot be fixed and the part must be scrapped. Positive tolerances are easier to achieve since they allow for secondary adjustments. For surfaces, holes, and outer diameters, it’s better to err on the larger side and gradually approach the correct dimension.

Why Only Machinable Ceramics Can Achieve Go/No-Go Gauge Compliance

Most ceramics cannot easily meet go/no-go gauge standards because it’s challenging to maintain dimensional consistency at the micron level. Sintered ceramics are hard and brittle, have low material removal rates, and edges chip easily. Machinable ceramics (like Macor) have a special internal structure that resists chipping, making them capable of consistently meeting go/no-go gauge requirements.

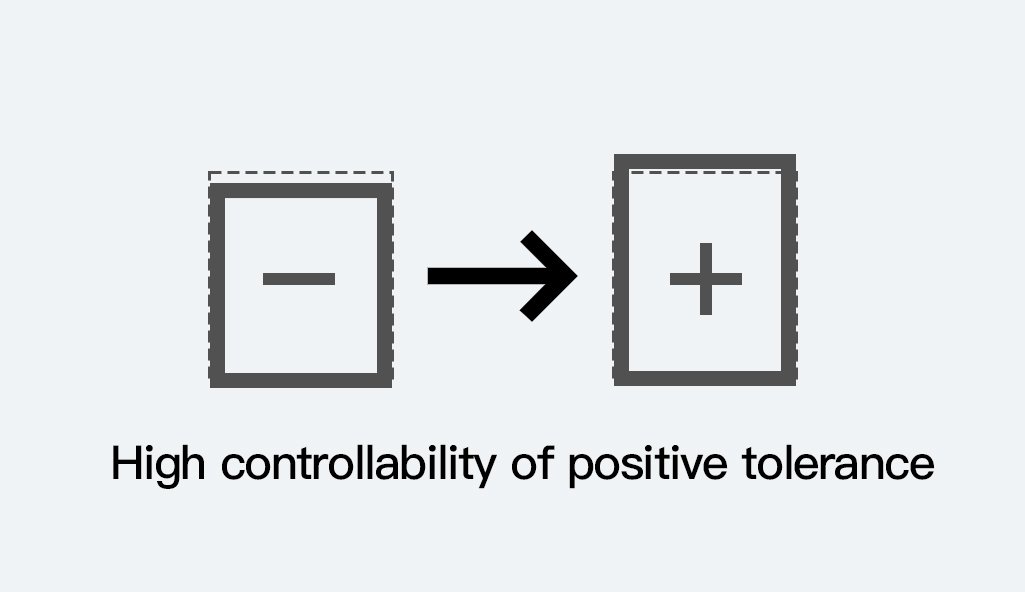

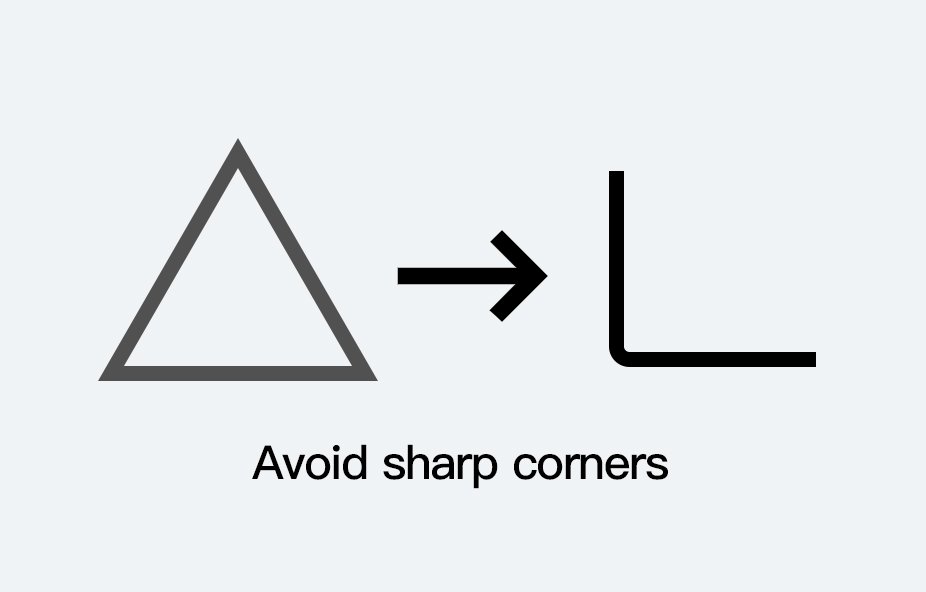

Why Ceramic Parts Should Avoid Sharp Corners

Sharp corners cause stress concentrations and can become crack initiation points during machining, sintering, or use. Ceramics have low fracture toughness, making sharp corners not only difficult to machine (rapid tool wear) but also prone to chipping during cooling or assembly. Designers should use fillets or rounded transitions to improve part strength and longevity.

Professional ceramic machining manufacturer

- Extensive Experience: Focused on precision ceramic machining since 2019

- Wide Range of Materials: Alumina, Aluminum Nitride, Macor, Zerodur, etc.

- High Precision Capabilities: Micron-level machining, controllable tolerances, meeting go/no-go requirements

- Customization Support: Supports complex structures, sharp corner optimization design, and functionalized machining

- Fast Delivery: A complete production system ensures a stable supply chain